Page 197 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 197

CH15pp159-189 4/10/02 12:51 PM Page 165

Applying the Process Model—A Case Study 165

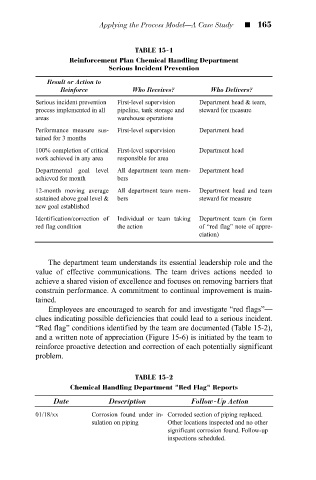

TABLE 15-1

Reinforcement Plan Chemical Handling Department

Serious Incident Prevention

Result or Action to

Reinforce Who Receives? Who Delivers?

Serious incident prevention First-level supervision Department head & team,

process implemented in all pipeline, tank storage and steward for measure

areas warehouse operations

Performance measure sus- First-level supervision Department head

tained for 3 months

100% completion of critical First-level supervision Department head

work achieved in any area responsible for area

Departmental goal level All department team mem- Department head

achieved for month bers

12-month moving average All department team mem- Department head and team

sustained above goal level & bers steward for measure

new goal established

Identification/correction of Individual or team taking Department team (in form

red flag condition the action of “red flag” note of appre-

ciation)

The department team understands its essential leadership role and the

value of effective communications. The team drives actions needed to

achieve a shared vision of excellence and focuses on removing barriers that

constrain performance. A commitment to continual improvement is main-

tained.

Employees are encouraged to search for and investigate “red flags”—

clues indicating possible deficiencies that could lead to a serious incident.

“Red flag” conditions identified by the team are documented (Table 15-2),

and a written note of appreciation (Figure 15-6) is initiated by the team to

reinforce proactive detection and correction of each potentially significant

problem.

TABLE 15-2

Chemical Handling Department "Red Flag" Reports

Date Description Follow-Up Action

01/18/xx Corrosion found under in- Corroded section of piping replaced.

sulation on piping Other locations inspected and no other

significant corrosion found. Follow-up

inspections scheduled.