Page 209 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 209

CH15pp159-189 4/10/02 12:51 PM Page 175

Applying the Process Model—A Case Study 175

800

700

600

S

c 500

o 400

r 300

e

200

100

0

1 2 3 4 5 6 7 8 9

Month

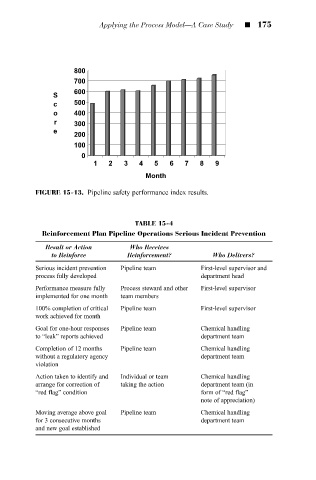

FIGURE 15-13. Pipeline safety performance index results.

TABLE 15-4

Reinforcement Plan Pipeline Operations Serious Incident Prevention

Result or Action Who Receives

to Reinforce Reinforcement? Who Delivers?

Serious incident prevention Pipeline team First-level supervisor and

process fully developed department head

Performance measure fully Process steward and other First-level supervisor

implemented for one month team members

100% completion of critical Pipeline team First-level supervisor

work achieved for month

Goal for one-hour responses Pipeline team Chemical handling

to “leak” reports achieved department team

Completion of 12 months Pipeline team Chemical handling

without a regulatory agency department team

violation

Action taken to identify and Individual or team Chemical handling

arrange for correction of taking the action department team (in

“red flag” condition form of “red flag”

note of appreciation)

Moving average above goal Pipeline team Chemical handling

for 3 consecutive months department team

and new goal established