Page 36 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 36

CH01pp001-020 4/10/02 12:49 PM Page 16

16

Establish effective policy for other

More effective accountability sys-

Improve emergency plan, conduct

Training of maintenance personnel

tem for parts and fasteners re-

including inspection process

vessels to escort tankers

moved

Tanker allowed to veer off course

Low level of emergency pre-

Multiple causes including:

$5 billion (ordered September 1994)

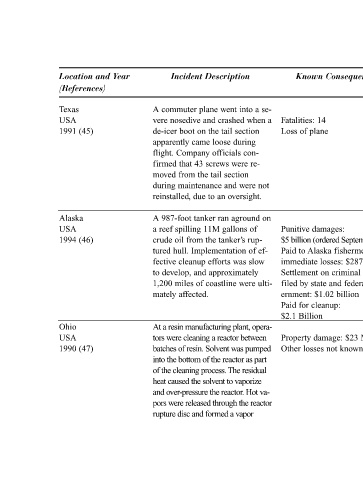

Known Consequences Potential Preventative Probable Cause Actions Effective maintenance procedures, Screws missing from tail section Serious Incident Prevention drills and audit preparedness paredness: Paid to Alaska fishermen for Provide adequate emergency re- a) response barge too small and immediate losses: $287 M sponse equi

Punitive damages:

Loss of plane

Fatalities: 14

Incident Description A commuter plane went into a se- vere nosedive and crashed when a de-icer boot on the tail section apparently came loose during flight. Company officials con- firmed that 43 screws were re- moved from the tail section during maintenance and were not reinstalled, due to an oversight. A 987-foot tanker ran agrou

Location and Year (References) Texas USA 1991 (45) Alaska USA 1994 (46) Ohio USA 1990 (47)