Page 32 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 32

CH01pp001-020 4/10/02 12:49 PM Page 14

Remote-operated emergency shut-

More effective permit system for

More effective prestartup inspec-

lines/equipment prior to start of

tion and test practices for tanks

Process to positively identify

off valves on wellheads.

maintenance activities

Adequate diking

work

standard hydrostatic test practices

Failure to use the most stringent

Cutting into line that contained

Failure of tank

pressure

Specific loss estimate not avail-

able. Fees for cleanup and legal

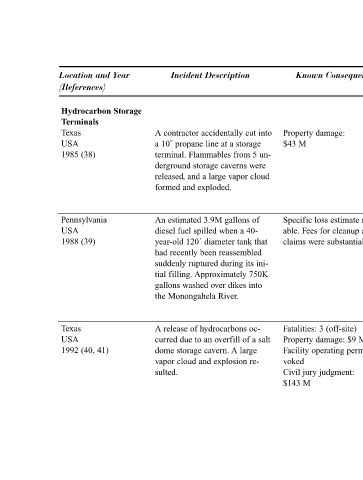

Known Consequences 14 Potential Preventative Probable Cause Actions Serious Incident Prevention prior to filling with diesel (tested by filling only 5´ of tank with water instead of entire tank) Accurate process for monitoring Failure of system designed to au- Fatalities: 3 (off-site) cavern inventory level tomatically close va

claims were substantial.

Property damage:

$43 M

Incident Description A contractor accidentally cut into a 10˝ propane line at a storage terminal. Flammables from 5 un- derground storage caverns were released, and a large vapor cloud formed and exploded. An estimated 3.9M gallons of diesel fuel spilled when a 40- year-old 120´ diameter tank that had recently been reassembled sud

Location and Year (References) Hydrocarbon Storage Terminals Texas USA 1985 (38) Pennsylvania USA 1988 (39) Texas USA 1992 (40, 41)