Page 37 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 37

CH01pp001-020 4/10/02 12:49 PM Page 16

16 Serious Incident Prevention

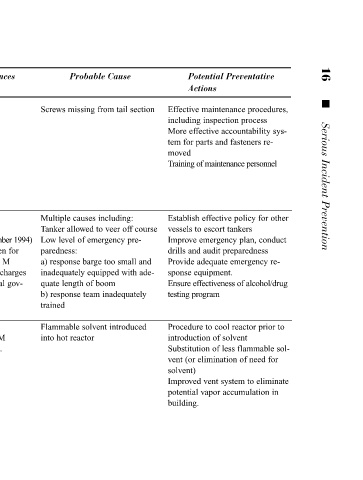

Potential Preventative Actions Effective maintenance procedures, including inspection process More effective accountability sys- tem for parts and fasteners re- moved Training of maintenance personnel Establish effective policy for other vessels to escort tankers Improve emergency plan, conduct drills and audit preparedness Provi

Probable Cause Screws missing from tail section Multiple causes including: Tanker allowed to veer off course Low level of emergency pre- paredness: a) response barge too small and inadequately equipped with ade- quate length of boom b) response team inadequately trained Flammable solvent introduced into hot reactor

Known Consequences Fatalities: 14 Loss of plane Punitive damages: $5 billion (ordered September 1994) Paid to Alaska fishermen for immediate losses: $287 M Settlement on criminal charges filed by state and federal gov- ernment: $1.02 billion Paid for cleanup: $2.1 Billion Property damage: $23 M Other losses not known.

Incident Description A commuter plane went into a se- vere nosedive and crashed when a de-icer boot on the tail section apparently came loose during flight. Company officials con- firmed that 43 screws were re- moved from the tail section during maintenance and were not reinstalled, due to an oversight. A 987-foot tanker ran agrou

Location and Year (References) Texas USA 1991 (45) Alaska USA 1994 (46) Ohio USA 1990 (47)