Page 35 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 35

CH01pp001-020 4/10/02 12:49 PM Page 15

The Improvement Challenge 15

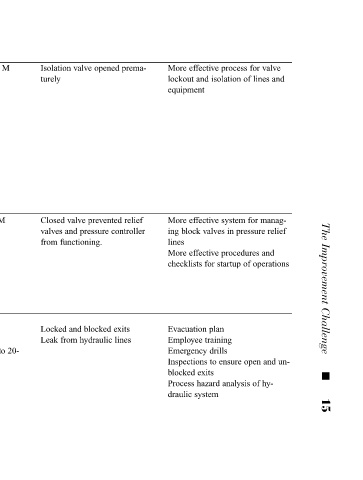

More effective process for valve lockout and isolation of lines and equipment More effective system for manag- ing block valves in pressure relief lines More effective procedures and checklists for startup of operations Evacuation plan Employee training Emergency drills Inspections to ensure open and un- blocked exits Process ha

Isolation valve opened prema- turely Closed valve prevented relief valves and pressure controller from functioning. Locked and blocked exits Leak from hydraulic lines

Property damage: $250 M Business interruption: $750 M Property damage: $50 M Fatalities: 25 OSHA fine: $810,000 Plant owner sentenced to 20- year prison term

After changing a leaking seal on an LPG pump, plant personnel were in the process of tightening a flange after removing an isolation blind on the pump’s suction line. LPG product began leaking from the flange and formed a vapor cloud that resulted in a series of explosions. Investigation indi- cated a motor-operated isolation valve in t

Gas Processing Plants Mexico 1996 (42) Bontang, Indonesia 1983 (43) Other North Carolina USA 1991 (44)