Page 27 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 27

CH01pp001-020 4/10/02 12:49 PM Page 11

The Improvement Challenge 11

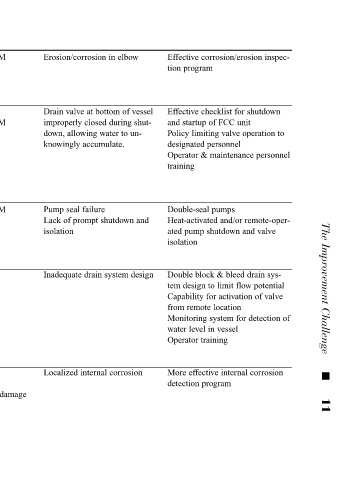

Effective corrosion/erosion inspec- tion program Effective checklist for shutdown and startup of FCC unit Policy limiting valve operation to designated personnel Operator & maintenance personnel training Double-seal pumps Heat-activated and/or remote-oper- ated pump shutdown and valve isolation Double block & bleed drain sys- tem

Erosion/corrosion in elbow Drain valve at bottom of vessel improperly closed during shut- down, allowing water to un- knowingly accumulate. Pump seal failure Lack of prompt shutdown and isolation Inadequate drain system design Localized internal corrosion

Property damage: $78 M Fatalities: 6 Property damage: $23 M Business interruption: $44 M OSHA settlement: $6 M Property damage: $25 M Business interruption: $76 M Property damage: $26.3 M Property damage: $254 M 5,200 off-site property damage claims reported

Explosion occurred following 6˝ carbon steel elbow rupture and release of hydrocarbon & hydro- gen mixture. During fluidic catalytic cracking (FCC) unit startup, superheated oil was introduced to vessel thought to be empty but which contained water. A steam explosion occurred rupturing vessel and starting fire that engulfed FCC unit.

California USA 1992 (24) Louisiana USA 1991 (25) Texas USA 1991 (26) Pennsylvania USA 1990 (27) Louisiana USA 1988 (28)