Page 22 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 22

CH01pp001-020 4/10/02 12:49 PM Page 8

8 Serious Incident Prevention

LESS

CONTROLLABLE

6%

NOT KNOWN

14%

CONTROLLABLE

80%

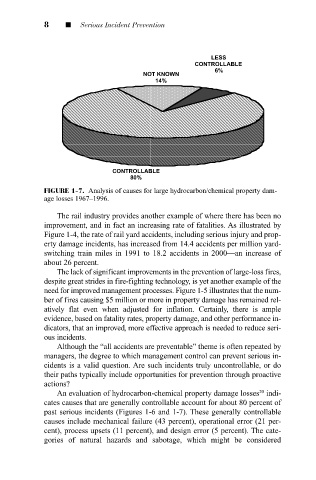

FIGURE 1-7. Analysis of causes for large hydrocarbon/chemical property dam-

age losses 1967–1996.

The rail industry provides another example of where there has been no

improvement, and in fact an increasing rate of fatalities. As illustrated by

Figure 1-4, the rate of rail yard accidents, including serious injury and prop-

erty damage incidents, has increased from 14.4 accidents per million yard-

switching train miles in 1991 to 18.2 accidents in 2000—an increase of

about 26 percent.

The lack of significant improvements in the prevention of large-loss fires,

despite great strides in fire-fighting technology, is yet another example of the

need for improved management processes. Figure 1-5 illustrates that the num-

ber of fires causing $5 million or more in property damage has remained rel-

atively flat even when adjusted for inflation. Certainly, there is ample

evidence, based on fatality rates, property damage, and other performance in-

dicators, that an improved, more effective approach is needed to reduce seri-

ous incidents.

Although the “all accidents are preventable” theme is often repeated by

managers, the degree to which management control can prevent serious in-

cidents is a valid question. Are such incidents truly uncontrollable, or do

their paths typically include opportunities for prevention through proactive

actions?

20

An evaluation of hydrocarbon-chemical property damage losses indi-

cates causes that are generally controllable account for about 80 percent of

past serious incidents (Figures 1-6 and 1-7). These generally controllable

causes include mechanical failure (43 percent), operational error (21 per-

cent), process upsets (11 percent), and design error (5 percent). The cate-

gories of natural hazards and sabotage, which might be considered