Page 25 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 25

CH01pp001-020 4/10/02 12:49 PM Page 10

10 Serious Incident Prevention

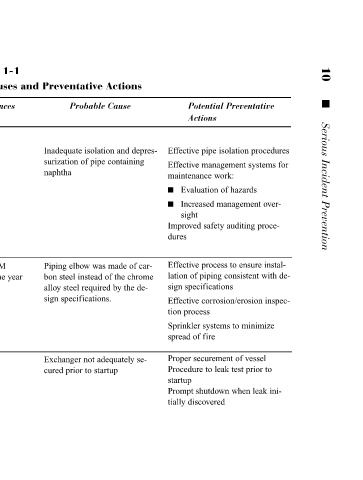

Potential Preventative Actions Effective pipe isolation procedures Effective management systems for maintenance work: Evaluation of hazards Increased management over- sight Improved safety auditing proce- dures Effective process to ensure instal- lation of piping consistent with de- sign specifications Effective c

Probable Cause Inadequate isolation and depres- surization of pipe containing naphtha Piping elbow was made of car- bon steel instead of the chrome alloy steel required by the de- sign specifications. Exchanger not adequately se- cured prior to startup

TABLE 1-1 Analysis of Serious Incident Causes and Preventative Actions Known Consequences Fatalities: 1 Injuries: 46 OSHA fine: $400,000 Property damage: $65 M Operating unit down one year Property damage: $161 M

Incident Description A fire occurred after naphtha was released from a pipe that was being replaced. At the time of the naphtha release and fire, workers were positioned on scaf- folding with limited means of es- cape. An intense fire occurred after a 6˝ diameter elbow ruptured and released hydrocarbons. The sus- tained heat

Location and Year (References) Refineries California USA 1999 (21) Louisiana USA 1993 (22) Sodegaura, Japan 1992 (23)