Page 29 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 29

CH01pp001-020 4/10/02 12:49 PM Page 12

12 Serious Incident Prevention

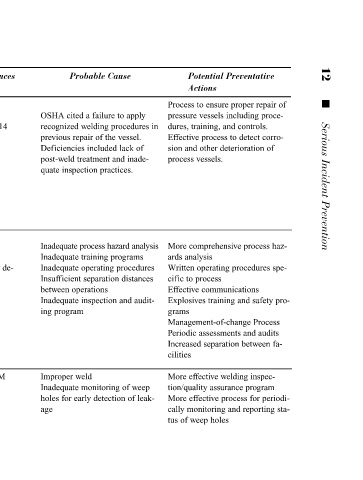

Potential Preventative Actions Process to ensure proper repair of pressure vessels including proce- dures, training, and controls. Effective process to detect corro- sion and other deterioration of process vessels. More comprehensive process haz- ards analysis Written operating procedures spe- cific to process Effective communi

Probable Cause OSHA cited a failure to apply recognized welding procedures in previous repair of the vessel. Deficiencies included lack of post-weld treatment and inade- quate inspection practices. Inadequate process hazard analysis Inadequate training programs Inadequate operating procedures Insufficient separation distances betwe

Known Consequences Fatalities: 17 Lost workday injuries: 14 Property damage: $191 M Fatalities: 4 Injuries: 6 Property damage: Plant de- stroyed Property damage: $25 M Business interruption: $20 M

Incident Description An operator was in the process of closing a valve to isolate a leak from a 6˝ horizontal crack at weld on a column. The crack spread to 24˝, and the column experienced total failure. Propane released at 200 psig propelled most of the 20-ton vessel 3,500´, where it toppled a 138KV power transmis- sion tower. An e

Location and Year (References) Illinois USA 1984 (29, 30) Chemical Facilities Nevada USA 1998 (31) Louisiana USA 1992 (32)