Page 139 - Shale Shakers Drilling Fluid Systems

P. 139

122 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

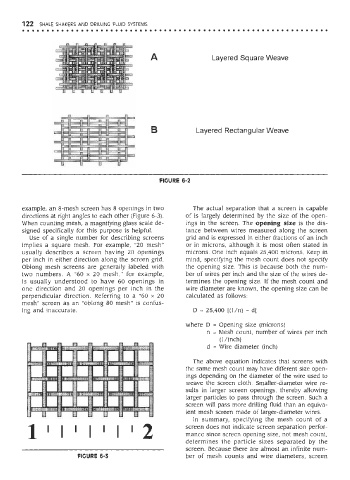

FIGURE 6-2

example, an 8-mesh screen has 8 openings in two The actual separation that a screen is capable

directions at right angles to each other (Figure 6-3). of is largely determined by the size of the open-

When counting mesh, a magnifying glass scale de- ings in the screen. The opening size is the dis-

signed specifically for this purpose is helpful. tance between wires measured along the screen

Use of a single number for describing screens grid and is expressed in either fractions of an inch

implies a square mesh. For example, "20 mesh" or in microns, although it is most often stated in

usually describes a screen having 20 openings microns. One inch equals 25,400 microns. Keep in

per inch in either direction along the screen grid. mind, specifying the mesh count does not specify

Oblong mesh screens are generally labeled with the opening size. This is because both the num-

two numbers. A "60 x 20 mesh," for example, ber of wires per inch and the size of the wires de-

is usually understood to have 60 openings in termines the opening size. If the mesh count and

one direction and 20 openings per inch in the wire diameter are known, the opening size can be

perpendicular direction. Referring to a "60 x 20 calculated as follows:

mesh" screen as an "oblong 80 mesh" is confus-

ing and inaccurate. D = 25,400 [(1/n) - d]

where D = Opening size (microns)

n = Mesh count, number of wires per inch

(I/inch)

d = Wire diameter (inch)

The above equation indicates that screens with

the same mesh count may have different size open-

ings depending on the diameter of the wire used to

weave the screen cloth. Smaller-diameter wire re-

sults in larger screen openings, thereby allowing

larger particles to pass through the screen. Such a

screen will pass more drilling fluid than an equiva-

lent mesh screen made of larger-diameter wires.

In summary, specifying the mesh count of a

screen does not indicate screen separation perfor-

mance since screen opening size, not mesh count,

determines the particle sizes separated by the

screen. Because there are almost an infinite num-

FIGURE 6-3 ber of mesh counts and wire diameters, screen