Page 143 - Shale Shakers Drilling Fluid Systems

P. 143

126 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

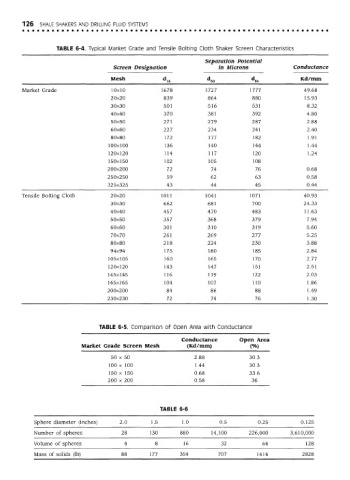

TABLE 6-4. Typical Market Grade and Tensile Bolting Cloth Shaker Screen Characteristics

Separation Potential

Screen Designation in Microns Conductance

Mesh Kd/mm

d 16 d so d 84

Market Grade 10x10 1678 1727 1777 49.68

20x20 839 864 880 15.93

30x30 501 516 531 8.32

40x40 370 381 392 4.80

50x50 271 279 287 2.88

60x60 227 234 241 2.40

80x80 172 177 182 1.91

100x100 136 140 144 1.44

120x120 114 117 120 1.24

150x150 102 105 108

200x200 72 74 76 0.68

250x250 59 62 63 0.58

325x325 43 44 45 0.44

Tensile Bolting Cloth 20x20 1011 1041 1071 40.93

30x30 662 681 700 24.33

40x40 457 470 483 11.63

50x50 357 368 379 7.94

60x60 301 310 319 5.60

70x70 261 269 277 5.25

80x80 218 224 230 3.88

94x94 175 180 185 2.84

105x105 160 165 170 2.77

120x120 143 147 151 2.51

145x145 116 119 122 2.03

165x165 104 107 110 1.86

200x200 84 86 88 1.49

230x230 72 74 76 1.30

TABLE 6-5. Comparison of Open Area with Conductance

Conductance Open Area

Market Grade Screen Mesh (Kd/mm) (%)

50 x 50 2.88 30.3

100 x 100 1.44 30.3

150 x 150 0.68 33.6

200 x 200 0.58 36

TABLE 6-6

Sphere diameter (inches) 2.0 1.5 1.0 0.5 0.25 0.125

Number of spheres 28 130 880 14,100 226,000 3,610,000

Volume of spheres 4 8 16 32 64 128

Mass of solids (Ib) 88 177 354 707 1414 2828