Page 257 - Shigley's Mechanical Engineering Design

P. 257

bud29281_ch05_212-264.qxd 11/27/2009 6:46 pm Page 232 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

232 Mechanical Engineering Design

For ductile materials with unequal yield strengths, S yt in tension and S yc in com-

pression, the Mohr theory is the best available. However, the theory requires the results

from three separate modes of tests, graphical construction of the failure locus, and fit-

ting the largest Mohr’s circle to the failure locus. The alternative to this is to use the

Coulomb-Mohr theory, which requires only the tensile and compressive yield strengths

and is easily dealt with in equation form.

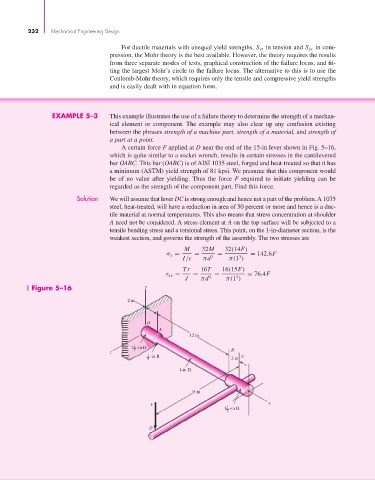

EXAMPLE 5–3 This example illustrates the use of a failure theory to determine the strength of a mechan-

ical element or component. The example may also clear up any confusion existing

between the phrases strength of a machine part, strength of a material, and strength of

a part at a point.

A certain force F applied at D near the end of the 15-in lever shown in Fig. 5–16,

which is quite similar to a socket wrench, results in certain stresses in the cantilevered

bar OABC. This bar (OABC) is of AISI 1035 steel, forged and heat-treated so that it has

a minimum (ASTM) yield strength of 81 kpsi. We presume that this component would

be of no value after yielding. Thus the force F required to initiate yielding can be

regarded as the strength of the component part. Find this force.

Solution We will assume that lever DC is strong enough and hence not a part of the problem. A 1035

steel, heat-treated, will have a reduction in area of 50 percent or more and hence is a duc-

tile material at normal temperatures. This also means that stress concentration at shoulder

A need not be considered. A stress element at A on the top surface will be subjected to a

tensile bending stress and a torsional stress. This point, on the 1-in-diameter section, is the

weakest section, and governs the strength of the assembly. The two stresses are

M 32M 32(14F)

σ x = = = = 142.6F

3

I/c πd 3 π(1 )

Tr 16T 16(15F)

τ zx = = = = 76.4F

3

J πd 3 π(1 )

Figure 5–16 y

2 in

O

A

12 in

1

1 -in D.

z 2 B

1 -in R. C

8 2 in

1-in D.

15 in

x

F

1

1 -in D.

2

D