Page 266 - Shigley's Mechanical Engineering Design

P. 266

bud29281_ch05_212-264.qxd 12/7/09 7:22PM Page 241 ntt G4 Mac OS 9.2:Desktop Folder:MHDQ196/Budynas:

Failures Resulting from Static Loading 241

Figure 5–22 y

b

x

a

Note that when a = b, the ellipse becomes a circle and Eq. (5–33) gives a stress-

concentration factor of 3. This agrees with the well-known result for an infinite plate with

a circular hole (see Table A–15–1). For a fine crack, b/a → 0, and Eq. (5–34) predicts

that (σ y ) max →∞. However, on a microscopic level, an infinitely sharp crack is a

hypothetical abstraction that is physically impossible, and when plastic deformation

occurs, the stress will be finite at the crack tip.

Griffith showed that the crack growth occurs when the energy release rate from

applied loading is greater than the rate of energy for crack growth. Crack growth can be

stable or unstable. Unstable crack growth occurs when the rate of change of the energy

release rate relative to the crack length is equal to or greater than the rate of change of

the crack growth rate of energy. Griffith’s experimental work was restricted to brittle

materials, namely glass, which pretty much confirmed his surface energy hypothesis.

However, for ductile materials, the energy needed to perform plastic work at the crack

tip is found to be much more crucial than surface energy.

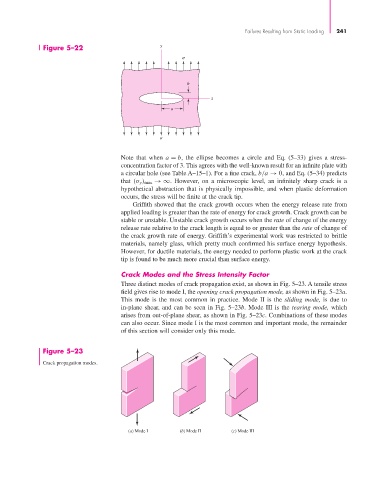

Crack Modes and the Stress Intensity Factor

Three distinct modes of crack propagation exist, as shown in Fig. 5–23. A tensile stress

field gives rise to mode I, the opening crack propagation mode, as shown in Fig. 5–23a.

This mode is the most common in practice. Mode II is the sliding mode, is due to

in-plane shear, and can be seen in Fig. 5–23b. Mode III is the tearing mode, which

arises from out-of-plane shear, as shown in Fig. 5–23c. Combinations of these modes

can also occur. Since mode I is the most common and important mode, the remainder

of this section will consider only this mode.

Figure 5–23

Crack propagation modes.

(a) Mode I (b) Mode II (c) Mode III