Page 270 - Shigley's Mechanical Engineering Design

P. 270

bud29281_ch05_212-264.qxd 11/27/2009 6:46 pm Page 245 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

Failures Resulting from Static Loading 245

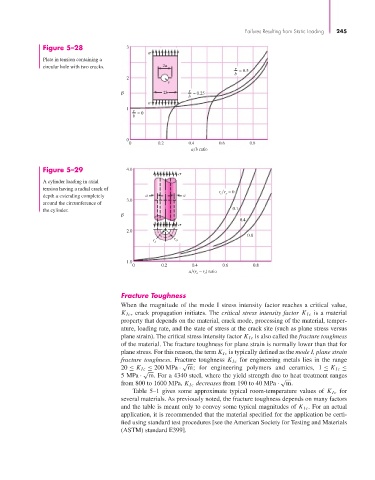

Figure 5–28 3

Plate in tension containing a

circular hole with two cracks. 2a

r = 0.5

b

2

r

2b r = 0.25

b

1

r = 0

b

0

0 0.2 0.4 0.6 0.8

a b ratio

Figure 5–29 4.0

A cylinder loading in axial

tension having a radial crack of

r r = 0

depth a extending completely a a i o

3.0

around the circumference of

the cylinder. 0.1

0.4

2.0

0.8

r i r o

1.0

0 0.2 0.4 0.6 0.8

a (r – r ) ratio

o i

Fracture Toughness

When the magnitude of the mode I stress intensity factor reaches a critical value,

K Ic , crack propagation initiates. The critical stress intensity factor K Ic is a material

property that depends on the material, crack mode, processing of the material, temper-

ature, loading rate, and the state of stress at the crack site (such as plane stress versus

plane strain). The critical stress intensity factor K Ic is also called the fracture toughness

of the material. The fracture toughness for plane strain is normally lower than that for

plane stress. For this reason, the term K Ic is typically defined as the mode I, plane strain

fracture toughness. Fracture toughness K Ic for engineering metals lies in the range

√

20 ≤ K Ic ≤ 200 MPa · m; for engineering polymers and ceramics, 1 ≤ K Ic ≤

√

5 MPa · m. For a 4340 steel, where the yield strength due to heat treatment ranges

√

from 800 to 1600 MPa, K Ic decreases from 190 to 40 MPa · m.

Table 5–1 gives some approximate typical room-temperature values of K Ic for

several materials. As previously noted, the fracture toughness depends on many factors

and the table is meant only to convey some typical magnitudes of K Ic . For an actual

application, it is recommended that the material specified for the application be certi-

fied using standard test procedures [see the American Society for Testing and Materials

(ASTM) standard E399].