Page 84 - Shigley's Mechanical Engineering Design

P. 84

bud29281_ch02_031-070.qxd 11/12/2009 7:59 pm Page 59 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

Materials 59

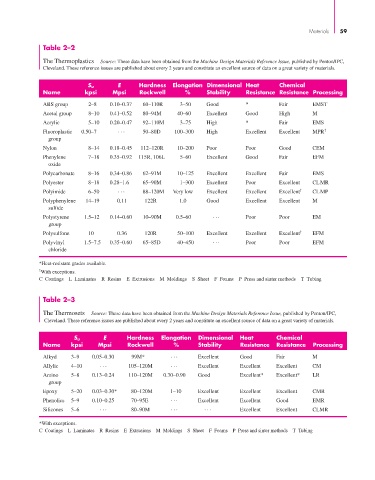

Table 2–2

The Thermoplastics Source: These data have been obtained from the Machine Design Materials Reference Issue, published by Penton/IPC,

Cleveland. These reference issues are published about every 2 years and constitute an excellent source of data on a great variety of materials.

E Hardness Elongation Dimensional Heat Chemical

S u

Name kpsi Mpsi Rockwell % Stability Resistance Resistance Processing

ABS group 2–8 0.10–0.37 60–110R 3–50 Good * Fair EMST

Acetal group 8–10 0.41–0.52 80–94M 40–60 Excellent Good High M

Acrylic 5–10 0.20–0.47 92–110M 3–75 High * Fair EMS

Fluoroplastic 0.50–7 ··· 50–80D 100–300 High Excellent Excellent MPR †

group

Nylon 8–14 0.18–0.45 112–120R 10–200 Poor Poor Good CEM

Phenylene 7–18 0.35–0.92 115R, 106L 5–60 Excellent Good Fair EFM

oxide

Polycarbonate 8–16 0.34–0.86 62–91M 10–125 Excellent Excellent Fair EMS

Polyester 8–18 0.28–1.6 65–90M 1–300 Excellent Poor Excellent CLMR

Polyimide 6–50 ··· 88–120M Very low Excellent Excellent Excellent † CLMP

Polyphenylene 14–19 0.11 122R 1.0 Good Excellent Excellent M

sulfide

Polystyrene 1.5–12 0.14–0.60 10–90M 0.5–60 ··· Poor Poor EM

group

Polysulfone 10 0.36 120R 50–100 Excellent Excellent Excellent † EFM

Polyvinyl 1.5–7.5 0.35–0.60 65–85D 40–450 ··· Poor Poor EFM

chloride

*Heat-resistant grades available.

†

With exceptions.

C Coatings L Laminates R Resins E Extrusions M Moldings S Sheet F Foams P Press and sinter methods T Tubing

Table 2–3

The Thermosets Source: These data have been obtained from the Machine Design Materials Reference Issue, published by Penton/IPC,

Cleveland. These reference issues are published about every 2 years and constitute an excellent source of data on a great variety of materials.

S u E Hardness Elongation Dimensional Heat Chemical

Name kpsi Mpsi Rockwell % Stability Resistance Resistance Processing

Alkyd 3–9 0.05–0.30 99M* ··· Excellent Good Fair M

Allylic 4–10 ··· 105–120M ··· Excellent Excellent Excellent CM

Amino 5–8 0.13–0.24 110–120M 0.30–0.90 Good Excellent* Excellent* LR

group

Epoxy 5–20 0.03–0.30* 80–120M 1–10 Excellent Excellent Excellent CMR

Phenolics 5–9 0.10–0.25 70–95E ··· Excellent Excellent Good EMR

Silicones 5–6 ··· 80–90M ··· ··· Excellent Excellent CLMR

*With exceptions.

C Coatings L Laminates R Resins E Extrusions M Moldings S Sheet F Foams P Press and sinter methods T Tubing