Page 88 - Shigley's Mechanical Engineering Design

P. 88

bud29281_ch02_031-070.qxd 11/11/09 09:34 PM Page 63 Debd Hard Disk1:Desktop Folder:Temp Work:Satya 10/11/09:

Materials 63

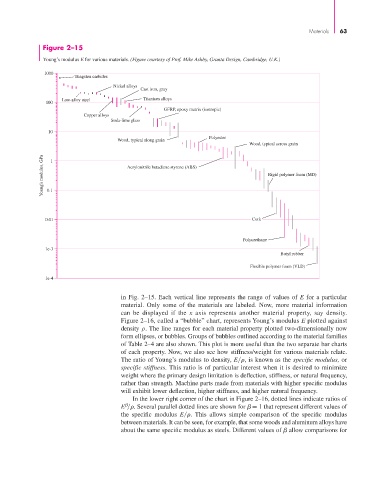

Figure 2–15

Young’s modulus E for various materials. (Figure courtesy of Prof. Mike Ashby, Granta Design, Cambridge, U.K.)

1000

Tungsten carbides

Nickel alloys

Cast iron, gray

Low-alloy steel Titanium alloys

100

GFRP, epoxy matrix (isotropic)

Copper alloys

Soda-lime glass

10

Polyester

Wood, typical along grain

Wood, typical across grain

Young's modulus, GPa 0.1 1 Acrylonitrile butadiene styrene (ABS) Rigid polymer foam (MD)

0.01 Cork

Polyurethane

1e-3

Butyl rubber

Flexible polymer foam (VLD)

1e-4

in Fig. 2–15. Each vertical line represents the range of values of E for a particular

material. Only some of the materials are labeled. Now, more material information

can be displayed if the x axis represents another material property, say density.

Figure 2–16, called a “bubble” chart, represents Young’s modulus E plotted against

density ρ. The line ranges for each material property plotted two-dimensionally now

form ellipses, or bubbles. Groups of bubbles outlined according to the material families

of Table 2–4 are also shown. This plot is more useful than the two separate bar charts

of each property. Now, we also see how stiffness/weight for various materials relate.

The ratio of Young’s modulus to density, E r, is known as the specific modulus, or

specific stiffness. This ratio is of particular interest when it is desired to minimize

weight where the primary design limitation is deflection, stiffness, or natural frequency,

rather than strength. Machine parts made from materials with higher specific modulus

will exhibit lower deflection, higher stiffness, and higher natural frequency.

In the lower right corner of the chart in Figure 2–16, dotted lines indicate ratios of

b

E r. Several parallel dotted lines are shown for b = 1 that represent different values of

the specific modulus E r. This allows simple comparison of the specific modulus

between materials. It can be seen, for example, that some woods and aluminum alloys have

about the same specific modulus as steels. Different values of b allow comparisons for