Page 91 - Shigley's Mechanical Engineering Design

P. 91

bud29281_ch02_031-070.qxd 11/11/09 09:35 PM Page 66 Debd Hard Disk1:Desktop Folder:Temp Work:Satya 10/11/09:

66 Mechanical Engineering Design

Figure 2–17 1000 3 1

Modulus–density Ceramics 0.3

A schematic E versus ρ chart Metals

showing a grid of lines for Search Composites

100 region

various values the material 0.1

index M = E 1/2 /ρ. (From Increasing values

Young's modulus E, GPa Woods E /

1/2

M. F. Ashby, Materials Selection of index E /

in Mechanical Design, 3rd ed., 10

Elsevier Butterworth- 1/2

1/2

Heinemann, Oxford, 2005.) 1 (GPa) /(Mg/m) 3

0.1 Foams Polymers

Elastomers

MFA 04

0.01

0.1 1 10 100

Density, Mg/m 3

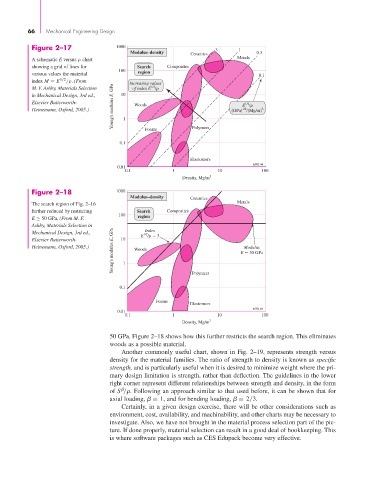

Figure 2–18 1000

Modulus–density Ceramics

The search region of Fig. 2–16 Metals

further reduced by restricting Search Composites

100 region

E ≥ 50 GPa, (From M. F.

Ashby, Materials Selection in

Young's modulus E, GPa 1 E 50 GPa

Index

Mechanical Design, 3rd ed., E / 3

1/2

Elsevier Butterworth- 10

Heinemann, Oxford, 2005.) Woods Modulus

0.1 Polymers

Foams

Elastomers

0.01 MFA 04

0.1 1 10 100

Density, Mg/m 3

50 GPa. Figure 2–18 shows how this further restricts the search region. This eliminates

woods as a possible material.

Another commonly useful chart, shown in Fig. 2–19, represents strength versus

density for the material families. The ratio of strength to density is known as specific

strength, and is particularly useful when it is desired to minimize weight where the pri-

mary design limitation is strength, rather than deflection. The guidelines in the lower

right corner represent different relationships between strength and density, in the form

b

of S r. Following an approach similar to that used before, it can be shown that for

axial loading, b = 1, and for bending loading, b = 2 3.

Certainly, in a given design exercise, there will be other considerations such as

environment, cost, availability, and machinability, and other charts may be necessary to

investigate. Also, we have not brought in the material process selection part of the pic-

ture. If done properly, material selection can result in a good deal of bookkeeping. This

is where software packages such as CES Edupack become very effective.