Page 92 - Shigley's Mechanical Engineering Design

P. 92

bud29281_ch02_031-070.qxd 11/11/09 09:35 PM Page 67 Debd Hard Disk1:Desktop Folder:Temp Work:Satya 10/11/09:

Materials 67

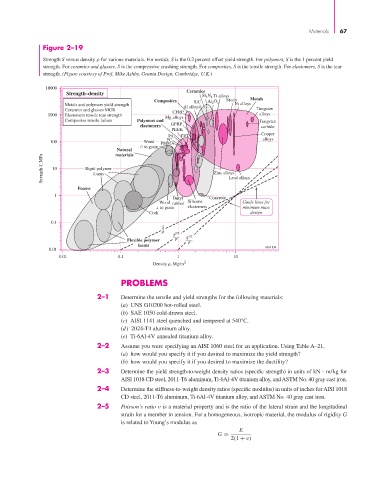

Figure 2–19

Strength S versus density ρ for various materials. For metals, S is the 0.2 percent offset yield strength. For polymers, S is the 1 percent yield

strength. For ceramics and glasses, S is the compressive crushing strength. For composites, S is the tensile strength. For elastomers, S is the tear

strength. (Figure courtesy of Prof. Mike Ashby, Granta Design, Cambridge, U.K.)

10000

Strength–density Ceramics Si N Ti alloys

Composites SiC 3 4 O Steels Metals

Metals and polymers yield strength A Al 2 3 Ni alloys

Al alloys

Ceramics and glasses MGR Tungsten

CFRP P

1000 Elastomers tensile tear strength Mg alloys P P P alloys

Composites tensile failure Polymers and Tungsten

elastomers GFRP carbide

PEEK

PA PET T Copper

PC

100 Wood PMMA alloys

to grain

Natural

materials

Strength S, MPa 10 Rigid polymer Zinc alloys

foams

Lead alloys

Foams

1

Butyl Concrete

Wood rubber Silicone Guide lines for

to grain elastomers minimum mass

Cork design

0.1

S

2/3

S 1/2

Flexible polymer S

foams MFA D4

0.01

0.01 0.1 1 10

Density , Mg/m 3

PROBLEMS

2–1 Determine the tensile and yield strengths for the following materials:

(a) UNS G10200 hot-rolled steel.

(b) SAE 1050 cold-drawn steel.

(c) AISI 1141 steel quenched and tempered at 540°C.

(d) 2024-T4 aluminum alloy.

(e) Ti-6Al-4V annealed titanium alloy.

2–2 Assume you were specifying an AISI 1060 steel for an application. Using Table A–21,

(a) how would you specify it if you desired to maximize the yield strength?

(b) how would you specify it if you desired to maximize the ductility?

2–3 Determine the yield strength-to-weight density ratios (specific strength) in units of kN m/kg for

AISI 1018 CD steel, 2011-T6 aluminum, Ti-6Al-4V titanium alloy, and ASTM No. 40 gray cast iron.

2–4 Determine the stiffness-to-weight density ratios (specific modulus) in units of inches for AISI 1018

CD steel, 2011-T6 aluminum, Ti-6Al-4V titanium alloy, and ASTM No. 40 gray cast iron.

2–5 Poisson’s ratio ν is a material property and is the ratio of the lateral strain and the longitudinal

strain for a member in tension. For a homogeneous, isotropic material, the modulus of rigidity G

is related to Young’s modulus as

E

G =

2(1 + ν)