Page 67 - Six Sigma for electronics design and manufacturing

P. 67

Six Sigma for Electronics Design and Manufacturing

36

When introducing control charts to a manufacturing operation, it is

preferred to use parameters that are universally recognized and with

simplified data collection, such as temperature and relative humidity,

or take readings from a process display monitor, such as the tempera-

ture indicator in a soldering system. These initial control charts can

be used to introduce and train the operators in data collection and

plotting of parameters. The same principles in selecting these ele-

ments also apply to six sigma parameter selections.

2.1.3 The process capability index (Cp)

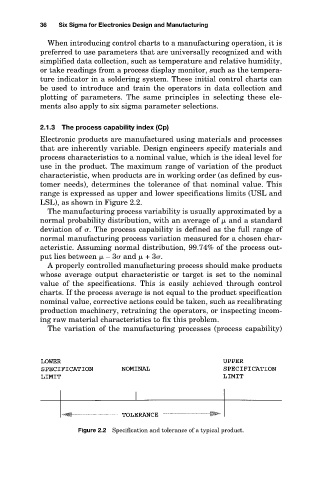

Electronic products are manufactured using materials and processes

that are inherently variable. Design engineers specify materials and

process characteristics to a nominal value, which is the ideal level for

use in the product. The maximum range of variation of the product

characteristic, when products are in working order (as defined by cus-

tomer needs), determines the tolerance of that nominal value. This

range is expressed as upper and lower specifications limits (USL and

LSL), as shown in Figure 2.2.

The manufacturing process variability is usually approximated by a

normal probability distribution, with an average of and a standard

deviation of . The process capability is defined as the full range of

normal manufacturing process variation measured for a chosen char-

acteristic. Assuming normal distribution, 99.74% of the process out-

put lies between – 3 and + 3 .

A properly controlled manufacturing process should make products

whose average output characteristic or target is set to the nominal

value of the specifications. This is easily achieved through control

charts. If the process average is not equal to the product specification

nominal value, corrective actions could be taken, such as recalibrating

production machinery, retraining the operators, or inspecting incom-

ing raw material characteristics to fix this problem.

The variation of the manufacturing processes (process capability)

Figure 2.2 Specification and tolerance of a typical product.