Page 72 - Six Sigma for electronics design and manufacturing

P. 72

The Elements of Six Sigma and Their Determination

41

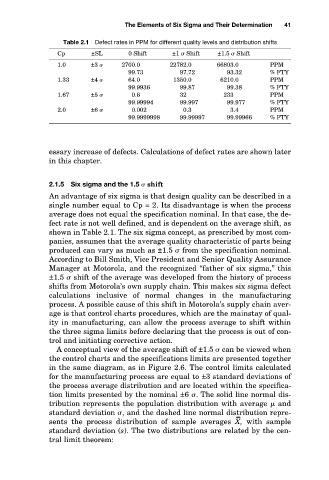

Table 2.1 Defect rates in PPM for different quality levels and distribution shifts

±1.5 Shift

±1 Shift

0 Shift

Cp

±SL

PPM

±3

22782.0

2700.0

1.0

66803.0

% FTY

99.73

93.32

97.72

1.33

PPM

64.0

1350.0

6210.0

±4

% FTY

99.9936

99.38

99.87

PPM

233

1.67

0.6

32

±5

99.977

% FTY

99.997

99.99994

0.002

2.0

3.4

PPM

0.3

±6

% FTY

99.99997

99.9999998

99.99966

essary increase of defects. Calculations of defect rates are shown later

in this chapter.

2.1.5 Six sigma and the 1.5 shift

An advantage of six sigma is that design quality can be described in a

single number equal to Cp = 2. Its disadvantage is when the process

average does not equal the specification nominal. In that case, the de-

fect rate is not well defined, and is dependent on the average shift, as

shown in Table 2.1. The six sigma concept, as prescribed by most com-

panies, assumes that the average quality characteristic of parts being

produced can vary as much as ±1.5 from the specification nominal.

According to Bill Smith, Vice President and Senior Quality Assurance

Manager at Motorola, and the recognized “father of six sigma,” this

±1.5 shift of the average was developed from the history of process

shifts from Motorola’s own supply chain. This makes six sigma defect

calculations inclusive of normal changes in the manufacturing

process. A possible cause of this shift in Motorola’s supply chain aver-

age is that control charts procedures, which are the mainstay of qual-

ity in manufacturing, can allow the process average to shift within

the three sigma limits before declaring that the process is out of con-

trol and initiating corrective action.

A conceptual view of the average shift of ±1.5 can be viewed when

the control charts and the specifications limits are presented together

in the same diagram, as in Figure 2.6. The control limits calculated

for the manufacturing process are equal to ±3 standard deviations of

the process average distribution and are located within the specifica-

tion limits presented by the nominal ±6 . The solid line normal dis-

tribution represents the population distribution with average and

standard deviation , and the dashed line normal distribution repre-

– –

sents the process distribution of sample averages X, with sample

standard deviation (s). The two distributions are related by the cen-

tral limit theorem: