Page 189 - Solid Waste Analysis and Minimization a Systems Approach

P. 189

STEP 7: DETERMINE, EVALUATE, AND SELECT WASTE MINIMIZATION ALTERNATIVES 167

■ What is the process if the equipment malfunctions and the company needs support?

Is there a representative available 24 hours per day? What is the charge for these

visits?

■ Do you offer an acceptance test process to ensure that the equipment operates with-

in the promised specifications (capacity and cycle time)?

■ What is the required installation time and must production be shut down?

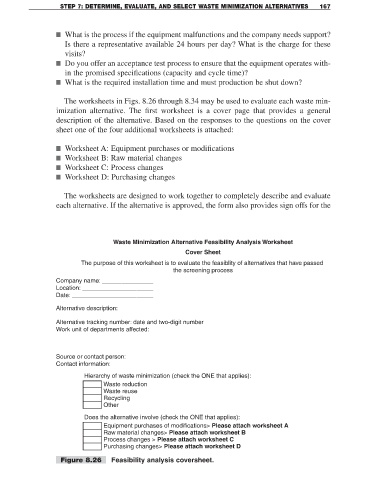

The worksheets in Figs. 8.26 through 8.34 may be used to evaluate each waste min-

imization alternative. The first worksheet is a cover page that provides a general

description of the alternative. Based on the responses to the questions on the cover

sheet one of the four additional worksheets is attached:

■ Worksheet A: Equipment purchases or modifications

■ Worksheet B: Raw material changes

■ Worksheet C: Process changes

■ Worksheet D: Purchasing changes

The worksheets are designed to work together to completely describe and evaluate

each alternative. If the alternative is approved, the form also provides sign offs for the

Waste Minimization Alternative Feasibility Analysis Worksheet

Cover Sheet

The purpose of this worksheet is to evaluate the feasiblity of alternatives that have passed

the screening process

Company name: ________________

Location: _____________________

Date: ________________________

Alternative description:

Alternative tracking number: date and two-digit number

Work unit of departments affected:

Source or contact person:

Contact information:

Hierarchy of waste minimization (check the ONE that applies):

Waste reduction

Waste reuse

Recycling

Other

Does the alternative involve (check the ONE that applies):

Equipment purchases of modifications> Please attach worksheet A

Raw material changes> Please attach worksheet B

Process changes > Please attach worksheet C

Purchasing changes> Please attach worksheet D

Figure 8.26 Feasibility analysis coversheet.