Page 194 - Solid Waste Analysis and Minimization a Systems Approach

P. 194

172 THE GENERAL APPROACH FOR A SOLID WASTE ASSESSMENT

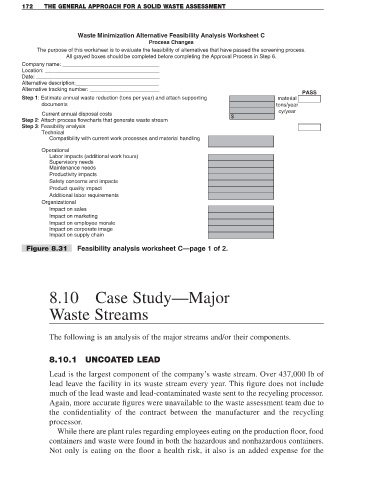

Waste Minimization Alternative Feasibility Analysis Worksheet C

Process Changes

The purpose of this worksheet is to evaluate the feasibility of alternatives that have passed the screening process.

All grayed boxes should be completed before completing the Approval Process in Step 6.

Company name: _________________________________

Location: _______________________________________

Date: __________________________________________

Alternative description:____________________________

Alternative tracking number: ________________________

PASS

Step 1: Estimate annual waste reduction (tons per year) and attach supporting material

documents tons/year

cy/year

Current annual disposal costs $

Step 2: Attach process flowcharts that generate waste stream

Step 3: Feasibility analysis

Technical

Compatibility with current work processes and material handling

Operational

Labor impacts (additional work hours)

Supervisory needs

Maintenance needs

Productivity impacts

Safety concerns and impacts

Product quality impact

Additional labor requirements

Organizational

Impact on sales

Impact on marketing

Impact on employee morale

Impact on corporate image

Impact on supply chain

Figure 8.31 Feasibility analysis worksheet C—page 1 of 2.

8.10 Case Study—Major

Waste Streams

The following is an analysis of the major streams and/or their components.

8.10.1 UNCOATED LEAD

Lead is the largest component of the company’s waste stream. Over 437,000 lb of

lead leave the facility in its waste stream every year. This figure does not include

much of the lead waste and lead-contaminated waste sent to the recyeling processor.

Again, more accurate figures were unavailable to the waste assessment team due to

the confidentiality of the contract between the manufacturer and the recycling

processor.

While there are plant rules regarding employees eating on the production floor, food

containers and waste were found in both the hazardous and nonhazardous containers.

Not only is eating on the floor a health risk, it also is an added expense for the