Page 196 - Solid Waste Analysis and Minimization a Systems Approach

P. 196

174 THE GENERAL APPROACH FOR A SOLID WASTE ASSESSMENT

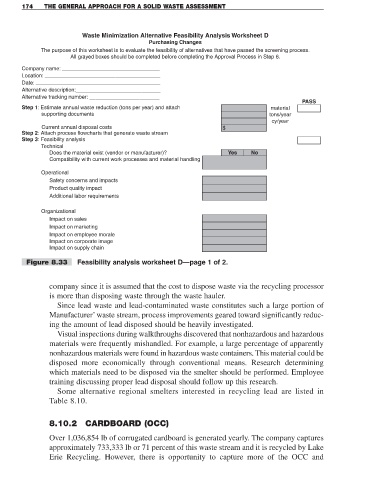

Waste Minimization Alternative Feasibility Analysis Worksheet D

Purchasing Changes

The purpose of this worksheet is to evaluate the feasibility of alternatives that have passed the screening process.

All grayed boxes should be completed before completing the Approval Process in Step 6.

Company name: _________________________________

Location: _______________________________________

Date: __________________________________________

Alternative description:_____________________________

Alternative tracking number: ________________________

PASS

Step 1: Estimate annual waste reduction (tons per year) and attach material

supporting documents tons/year

cy/year

Current annual disposal costs $

Step 2: Attach process flowcharts that generate waste stream

Step 3: Feasibility analysis

Technical

Does the material exist (vendor or manufacturer)? Yes No

Compatibility with current work processes and material handling

Operational

Safety concerns and impacts

Product quality impact

Additional labor requirements

Organizational

Impact on sales

Impact on marketing

Impact on employee morale

Impact on corporate image

Impact on supply chain

Figure 8.33 Feasibility analysis worksheet D—page 1 of 2.

company since it is assumed that the cost to dispose waste via the recycling processor

is more than disposing waste through the waste hauler.

Since lead waste and lead-contaminated waste constitutes such a large portion of

Manufacturer’ waste stream, process improvements geared toward significantly reduc-

ing the amount of lead disposed should be heavily investigated.

Visual inspections during walkthroughs discovered that nonhazardous and hazardous

materials were frequently mishandled. For example, a large percentage of apparently

nonhazardous materials were found in hazardous waste containers. This material could be

disposed more economically through conventional means. Research determining

which materials need to be disposed via the smelter should be performed. Employee

training discussing proper lead disposal should follow up this research.

Some alternative regional smelters interested in recycling lead are listed in

Table 8.10.

8.10.2 CARDBOARD (OCC)

Over 1,036,854 lb of corrugated cardboard is generated yearly. The company captures

approximately 733,333 lb or 71 percent of this waste stream and it is recycled by Lake

Erie Recycling. However, there is opportunity to capture more of the OCC and