Page 190 - Solid Waste Analysis and Minimization a Systems Approach

P. 190

168 THE GENERAL APPROACH FOR A SOLID WASTE ASSESSMENT

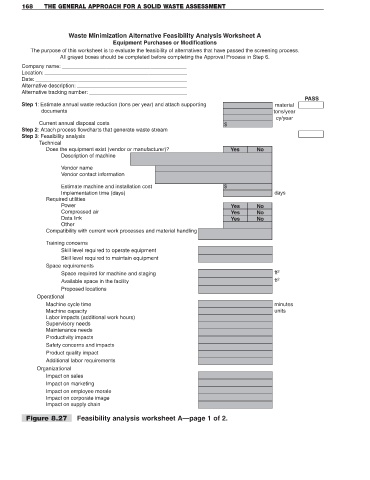

Waste Minimization Alternative Feasibility Analysis Worksheet A

Equipment Purchases or Modifications

The purpose of this worksheet is to evaluate the feasibility of alternatives that have passed the screening process.

All grayed boxes should be completed before completing the Approval Process in Step 6.

Company name: __________________________________________

Location: ________________________________________________

Date: ___________________________________________________

Alternative description: _____________________________________

Alternative tracking number: _________________________________

PASS

Step 1: Estimate annual waste reduction (tons per year) and attach supporting material

documents tons/year

cy/year

Current annual disposal costs $

Step 2: Attach process flowcharts that generate waste stream

Step 3: Feasibility analysis

Technical

Does the equipment exist (vendor or manufacturer)? Yes No

Description of machine

Vendor name

Vendor contact information

Estimate machine and installation cost $

Implementation time (days) days

Required utilities

Power Yes No

Compressed air Yes No

Data link Yes No

Other

Compatibility with current work processes and material handling

Training concerns

Skill level required to operate equipment

Skill level required to maintain equipment

Space requirements

Space required for machine and staging ft 2

Available space in the facility ft 2

Proposed locations

Operational

Machine cycle time minutes

Machine capacity units

Labor impacts (additional work hours)

Supervisory needs

Maintenance needs

Productivity impacts

Safety concerns and impacts

Product quality impact

Additional labor requirements

Organizational

Impact on sales

Impact on marketing

Impact on employee morale

Impact on corporate image

Impact on supply chain

Figure 8.27 Feasibility analysis worksheet A—page 1 of 2.