Page 462 - Solid Waste Analysis and Minimization a Systems Approach

P. 462

440 INDUSTRIAL AND COMMERCIAL MACHINERY INCLUDING AUTOMOTIVE MANUFACTURING

cans, metal-stamping scrap, plastic-stamping scrap, and oily wastewater. The facility

2

was 790,000 ft and operated 7 days per week. The annual waste hauling costs were

$25,080, which included special wastes.

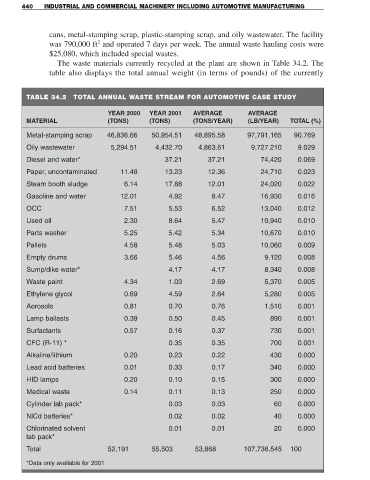

The waste materials currently recycled at the plant are shown in Table 34.2. The

table also displays the total annual weight (in terms of pounds) of the currently

TABLE 34.2 TOTAL ANNUAL WASTE STREAM FOR AUTOMOTIVE CASE STUDY

YEAR 2000 YEAR 2001 AVERAGE AVERAGE

MATERIAL (TONS) (TONS) (TONS/YEAR) (LB/YEAR) TOTAL (%)

Metal-stamping scrap 46,836.66 50,954.51 48,895.58 97,791,165 90.769

Oily wastewater 5,294.51 4,432.70 4,863.61 9,727,210 9.029

Diesel and water* 37.21 37.21 74,420 0.069

Paper, uncontaminated 11.48 13.23 12.36 24,710 0.023

Steam booth sludge 6.14 17.88 12.01 24,020 0.022

Gasoline and water 12.01 4.92 8.47 16,930 0.016

OCC 7.51 5.53 6.52 13,040 0.012

Used oil 2.30 8.64 5.47 10,940 0.010

Parts washer 5.25 5.42 5.34 10,670 0.010

Pallets 4.58 5.48 5.03 10,060 0.009

Empty drums 3.66 5.46 4.56 9,120 0.008

Sump/dike water* 4.17 4.17 8,340 0.008

Waste paint 4.34 1.03 2.69 5,370 0.005

Ethylene glycol 0.69 4.59 2.64 5,280 0.005

Aerosols 0.81 0.70 0.76 1,510 0.001

Lamp ballasts 0.39 0.50 0.45 890 0.001

Surfactants 0.57 0.16 0.37 730 0.001

CFC (R-11) * 0.35 0.35 700 0.001

Alkaline/lithium 0.20 0.23 0.22 430 0.000

Lead acid batteries 0.01 0.33 0.17 340 0.000

HID lamps 0.20 0.10 0.15 300 0.000

Medical waste 0.14 0.11 0.13 250 0.000

Cylinder lab pack* 0.03 0.03 60 0.000

NiCd batteries* 0.02 0.02 40 0.000

Chlorinated solvent 0.01 0.01 20 0.000

lab pack*

Total 52,191 55,503 53,868 107,736,545 100

*Data only available for 2001