Page 101 - Steam Turbines Design, Applications, and Rerating

P. 101

82 Chapter Four

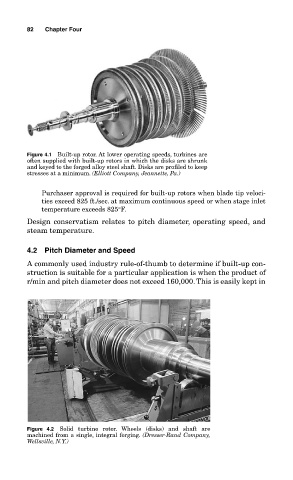

Figure 4.1 Built-up rotor. At lower operating speeds, turbines are

often supplied with built-up rotors in which the disks are shrunk

and keyed to the forged alloy steel shaft. Disks are profiled to keep

stresses at a minimum. (Elliott Company, Jeannette, Pa.)

Purchaser approval is required for built-up rotors when blade tip veloci-

ties exceed 825 ft./sec. at maximum continuous speed or when stage inlet

temperature exceeds 825°F.

Design conservatism relates to pitch diameter, operating speed, and

steam temperature.

4.2 Pitch Diameter and Speed

A commonly used industry rule-of-thumb to determine if built-up con-

struction is suitable for a particular application is when the product of

r/min and pitch diameter does not exceed 160,000. This is easily kept in

Figure 4.2 Solid turbine rotor. Wheels (disks) and shaft are

machined from a single, integral forging. (Dresser-Rand Company,

Wellsville, N.Y.)