Page 106 - Steam Turbines Design, Applications, and Rerating

P. 106

Rotors for Impulse Turbines 87

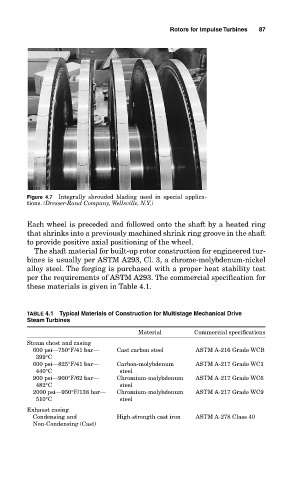

Figure 4.7 Integrally shrouded blading used in special applica-

tions. (Dresser-Rand Company, Wellsville, N.Y.)

Each wheel is preceded and followed onto the shaft by a heated ring

that shrinks into a previously machined shrink ring groove in the shaft

to provide positive axial positioning of the wheel.

The shaft material for built-up rotor construction for engineered tur-

bines is usually per ASTM A293, Cl. 3, a chrome-molybdenum-nickel

alloy steel. The forging is purchased with a proper heat stability test

per the requirements of ASTM A293. The commercial specification for

these materials is given in Table 4.1.

TABLE 4.1 Typical Materials of Construction for Multistage Mechanical Drive

Steam Turbines

Material Commercial specifications

Steam chest and casing

600 psi—750°F/41 bar— Cast carbon steel ASTM A-216 Grade WCB

399°C

600 psi—825°F/41 bar— Carbon-molybdenum ASTM A-217 Grade WC1

440°C steel

900 psi—900°F/62 bar— Chromium-molybdenum ASTM A-217 Grade WC6

482°C steel

2000 psi—950°F/138 bar— Chromium-molybdenum ASTM A-217 Grade WC9

510°C steel

Exhaust casing

Condensing and High-strength cast iron ASTM A-278 Class 40

Non-Condensing (Cast)