Page 109 - Steam Turbines Design, Applications, and Rerating

P. 109

90 Chapter Four

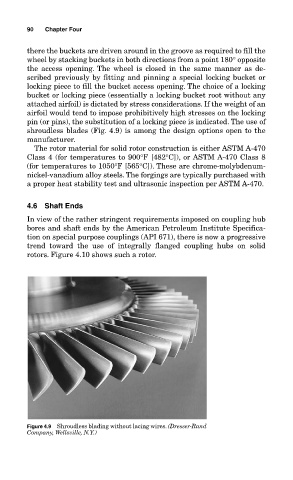

there the buckets are driven around in the groove as required to fill the

wheel by stacking buckets in both directions from a point 180° opposite

the access opening. The wheel is closed in the same manner as de-

scribed previously by fitting and pinning a special locking bucket or

locking piece to fill the bucket access opening. The choice of a locking

bucket or locking piece (essentially a locking bucket root without any

attached airfoil) is dictated by stress considerations. If the weight of an

airfoil would tend to impose prohibitively high stresses on the locking

pin (or pins), the substitution of a locking piece is indicated. The use of

shroudless blades (Fig. 4.9) is among the design options open to the

manufacturer.

The rotor material for solid rotor construction is either ASTM A-470

Class 4 (for temperatures to 900°F [482°C]), or ASTM A-470 Class 8

(for temperatures to 1050°F [565°C]). These are chrome-molybdenum-

nickel-vanadium alloy steels. The forgings are typically purchased with

a proper heat stability test and ultrasonic inspection per ASTM A-470.

4.6 Shaft Ends

In view of the rather stringent requirements imposed on coupling hub

bores and shaft ends by the American Petroleum Institute Specifica-

tion on special purpose couplings (API 671), there is now a progressive

trend toward the use of integrally flanged coupling hubs on solid

rotors. Figure 4.10 shows such a rotor.

Figure 4.9 Shroudless blading without lacing wires. (Dresser-Rand

Company, Wellsville, N.Y.)