Page 119 - Steam Turbines Design, Applications, and Rerating

P. 119

100 Chapter Five

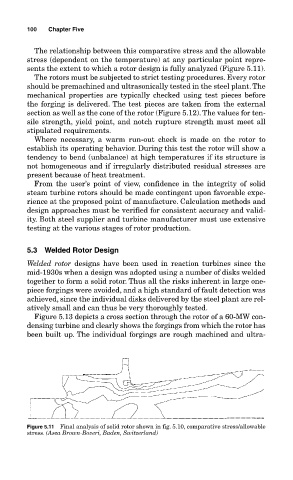

The relationship between this comparative stress and the allowable

stress (dependent on the temperature) at any particular point repre-

sents the extent to which a rotor design is fully analyzed (Figure 5.11).

The rotors must be subjected to strict testing procedures. Every rotor

should be premachined and ultrasonically tested in the steel plant. The

mechanical properties are typically checked using test pieces before

the forging is delivered. The test pieces are taken from the external

section as well as the cone of the rotor (Figure 5.12). The values for ten-

sile strength, yield point, and notch rupture strength must meet all

stipulated requirements.

Where necessary, a warm run-out check is made on the rotor to

establish its operating behavior. During this test the rotor will show a

tendency to bend (unbalance) at high temperatures if its structure is

not homogeneous and if irregularly distributed residual stresses are

present because of heat treatment.

From the user’s point of view, confidence in the integrity of solid

steam turbine rotors should be made contingent upon favorable expe-

rience at the proposed point of manufacture. Calculation methods and

design approaches must be verified for consistent accuracy and valid-

ity. Both steel supplier and turbine manufacturer must use extensive

testing at the various stages of rotor production.

5.3 Welded Rotor Design

Welded rotor designs have been used in reaction turbines since the

mid-1930s when a design was adopted using a number of disks welded

together to form a solid rotor. Thus all the risks inherent in large one-

piece forgings were avoided, and a high standard of fault detection was

achieved, since the individual disks delivered by the steel plant are rel-

atively small and can thus be very thoroughly tested.

Figure 5.13 depicts a cross section through the rotor of a 60-MW con-

densing turbine and clearly shows the forgings from which the rotor has

been built up. The individual forgings are rough machined and ultra-

Figure 5.11 Final analysis of solid rotor shown in fig. 5.10, comparative stress/allowable

stress. (Asea Brown-Boveri, Baden, Switzerland)