Page 120 - Steam Turbines Design, Applications, and Rerating

P. 120

Rotors for Reaction Turbines 101

Figure 5.12 Location of test pieces, (1) and (2), for

strength testing of solid rotors. (Asea Brown-

Boveri, Baden, Switzerland)

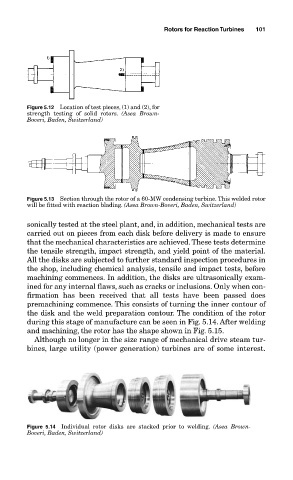

Figure 5.13 Section through the rotor of a 60-MW condensing turbine. This welded rotor

will be fitted with reaction blading. (Asea Brown-Boveri, Baden, Switzerland)

sonically tested at the steel plant, and, in addition, mechanical tests are

carried out on pieces from each disk before delivery is made to ensure

that the mechanical characteristics are achieved. These tests determine

the tensile strength, impact strength, and yield point of the material.

All the disks are subjected to further standard inspection procedures in

the shop, including chemical analysis, tensile and impact tests, before

machining commences. In addition, the disks are ultrasonically exam-

ined for any internal flaws, such as cracks or inclusions. Only when con-

firmation has been received that all tests have been passed does

premachining commence. This consists of turning the inner contour of

the disk and the weld preparation contour. The condition of the rotor

during this stage of manufacture can be seen in Fig. 5.14. After welding

and machining, the rotor has the shape shown in Fig. 5.15.

Although no longer in the size range of mechanical drive steam tur-

bines, large utility (power generation) turbines are of some interest.

Figure 5.14 Individual rotor disks are stacked prior to welding. (Asea Brown-

Boveri, Baden, Switzerland)