Page 255 - Steam Turbines Design, Applications, and Rerating

P. 255

234 Chapter Twelve

■ The nozzle chest at the steam inlet provides flexibility and, in par-

ticular, short starting times (Fig. 12.14).

■ If necessary, separate fixed blade carriers are fitted to facilitate ther-

mal expansion (Fig. 12.15).

■ Welded rotor construction and its possible advantages have been dis-

cussed earlier. One-piece rotors can also be built for small machines.

■ Movable segments in the shaft seals at balance piston and casing

penetrations for the higher ratings.

■ Securely fixed control-stage blades, welded if necessary.

■ Reaction blading of rugged construction.

Reaction type mechanical drive turbines have been performing sat-

isfactorily for decades, proving the suitability of the design. This is fur-

ther supported by the fact that some of the largest mechanical drive

units in the world are the reaction type. A good example is the 50-MW

feedpump turbine for a 1350-MW Asea Brown-Boveri steam turbine at

a power generating plant in the United States that has been running

successfully since 1973. In the late 1970s several 100-MW compressor

drive turbines were put in service at Skikda, Algeria. They, and others

since then, have run without problems.

It should be noted that since the earliest days of the steam turbine

the impulse and reaction types of construction have existed side by

side. That neither has been able to supersede the other in any field of

application—whether for mechanical drives or power-generating

plants—implies that neither type is fundamentally better than the

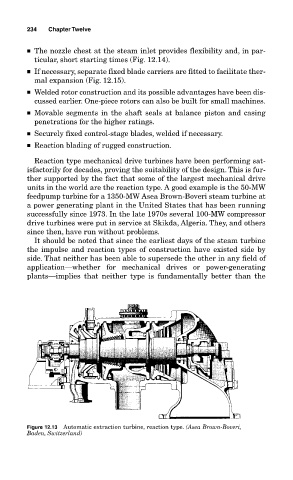

Figure 12.13 Automatic extraction turbine, reaction type. (Asea Brown-Boveri,

Baden, Switzerland)