Page 256 - Steam Turbines Design, Applications, and Rerating

P. 256

Reaction vs. Impulse Type Steam Turbines 235

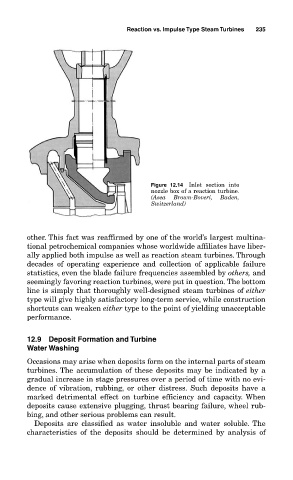

Figure 12.14 Inlet section into

nozzle box of a reaction turbine.

(Asea Brown-Boveri, Baden,

Switzerland)

other. This fact was reaffirmed by one of the world’s largest multina-

tional petrochemical companies whose worldwide affiliates have liber-

ally applied both impulse as well as reaction steam turbines. Through

decades of operating experience and collection of applicable failure

statistics, even the blade failure frequencies assembled by others, and

seemingly favoring reaction turbines, were put in question. The bottom

line is simply that thoroughly well-designed steam turbines of either

type will give highly satisfactory long-term service, while construction

shortcuts can weaken either type to the point of yielding unacceptable

performance.

12.9 Deposit Formation and Turbine

Water Washing

Occasions may arise when deposits form on the internal parts of steam

turbines. The accumulation of these deposits may be indicated by a

gradual increase in stage pressures over a period of time with no evi-

dence of vibration, rubbing, or other distress. Such deposits have a

marked detrimental effect on turbine efficiency and capacity. When

deposits cause extensive plugging, thrust bearing failure, wheel rub-

bing, and other serious problems can result.

Deposits are classified as water insoluble and water soluble. The

characteristics of the deposits should be determined by analysis of