Page 259 - Steam Turbines Design, Applications, and Rerating

P. 259

238 Chapter Twelve

injection pumps presents a great hazard, especially at maximum injec-

tion rates. To guard against pump failure, untreated boiler feedwater is

used since these pumps are usually the most reliable in a plant.

If plant-operating conditions allow, the vacuum on a condensing tur-

bine should be reduced to 5 to 10 mmHg; for noncondensing turbines,

the exhaust pressure should be reduced to atmospheric pressure. Note

that on any noncondensing unit requiring full-speed washing, the

manufacturer should be consulted about minimum allowable exhaust

pressure. Extraction turbines should be run with the extraction line

shut off.

A steam gauge and thermometer should be installed between the

trip-throttle valve and the governor-controlled valves. The thermome-

ter should preferably be a recording type and should be very responsive

to small changes in temperature.

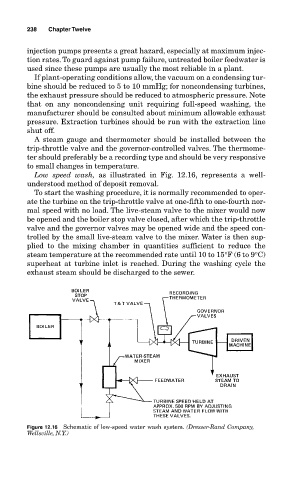

Low speed wash, as illustrated in Fig. 12.16, represents a well-

understood method of deposit removal.

To start the washing procedure, it is normally recommended to oper-

ate the turbine on the trip-throttle valve at one-fifth to one-fourth nor-

mal speed with no load. The live-steam valve to the mixer would now

be opened and the boiler stop valve closed, after which the trip-throttle

valve and the governor valves may be opened wide and the speed con-

trolled by the small live-steam valve to the mixer. Water is then sup-

plied to the mixing chamber in quantities sufficient to reduce the

steam temperature at the recommended rate until 10 to 15°F (6 to 9°C)

superheat at turbine inlet is reached. During the washing cycle the

exhaust steam should be discharged to the sewer.

Figure 12.16 Schematic of low-speed water wash system. (Dresser-Rand Company,

Wellsville, N.Y.)