Page 134 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 134

Brockenbrough_Ch03.qxd 9/29/05 5:05 PM Page 3.66

CONNECTIONS

3.66 CHAPTER THREE

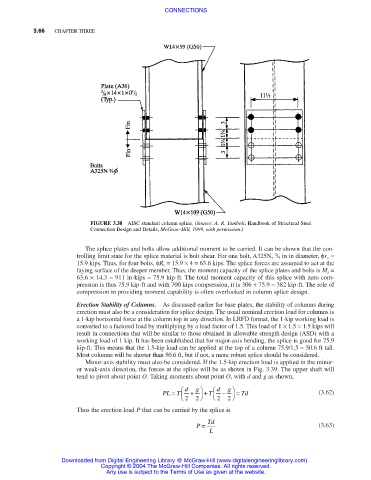

FIGURE 3.38 AISC standard column splice. (Source: A. R. Tamboli, Handbook of Structural Steel

Connection Design and Details, McGraw-Hill, 1999, with permission.)

The splice plates and bolts allow additional moment to be carried. It can be shown that the con-

trolling limit state for the splice material is bolt shear. For one bolt, A325N, / 4 in in diameter, φr v =

3

15.9 kips. Thus, for four bolts, φR v = 15.9 × 4 = 63.6 kips. The splice forces are assumed to act at the

faying surface of the deeper member. Thus, the moment capacity of the splice plates and bolts is M s =

63.6 × 14.3 = 911 in⋅kips = 75.9 kip⋅ft. The total moment capacity of this splice with zero com-

pression is thus 75.9 kip⋅ft and with 700 kips compression, it is 306 + 75.9 = 382 kip⋅ft. The role of

compression in providing moment capability is often overlooked in column splice design.

Erection Stability of Columns. As discussed earlier for base plates, the stability of columns during

erection must also be a consideration for splice design. The usual nominal erection load for columns is

a 1-kip horizontal force at the column top in any direction. In LRFD format, the 1-kip working load is

converted to a factored load by multiplying by a load factor of 1.5. This load of 1 × 1.5 = 1.5 kips will

result in connections that will be similar to those obtained in allowable strength design (ASD) with a

working load of 1 kip. It has been established that for major-axis bending, the splice is good for 75.9

kip⋅ft. This means that the 1.5-kip load can be applied at the top of a column 75.9/1.5 = 50.6 ft tall.

Most columns will be shorter than 50.6 ft, but if not, a more robust splice should be considered.

Minor-axis stability must also be considered. If the 1.5-kip erection load is applied in the minor-

or weak-axis direction, the forces at the splice will be as shown in Fig. 3.39. The upper shaft will

tend to pivot about point O. Taking moments about point O, with d and g as shown,

PL = T d + g + T d − g = Td (3.62)

2 2 2 2

Thus the erection load P that can be carried by the splice is

P = Td (3.63)

L

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.