Page 106 - Sustainability in the Process Industry Integration and Optimization

P. 106

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 83

the positions of some matches often results in complicated path

representations.

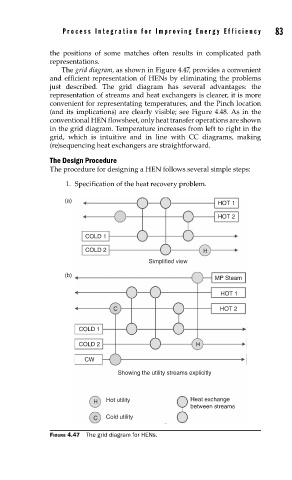

The grid diagram, as shown in Figure 4.47, provides a convenient

and efficient representation of HENs by eliminating the problems

just described. The grid diagram has several advantages: the

representation of streams and heat exchangers is clearer, it is more

convenient for representating temperatures, and the Pinch location

(and its implications) are clearly visible; see Figure 4.48. As in the

conventional HEN flowsheet, only heat transfer operations are shown

in the grid diagram. Temperature increases from left to right in the

grid, which is intuitive and in line with CC diagrams, making

(re)sequencing heat exchangers are straightforward.

The Design Procedure

The procedure for designing a HEN follows several simple steps:

1. Specification of the heat recovery problem.

(a)

HOT 1

HOT 2

COLD 1

COLD 2 H

Simplified view

(b)

MP Steam

HOT 1

C HOT 2

COLD 1

COLD 2 H

CW

Showing the utility streams explicitly

H Hot utility Heat exchange

between streams

C Cold utility

FIGURE 4.47 The grid diagram for HENs.