Page 110 - Sustainability in the Process Industry Integration and Optimization

P. 110

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 87

of a hot stream if a feasible essential match is to result. Generalizing

Eq. (4.9) shows that the CP of the stream entering the Pinch must be

less than or equal to the CP of the stream leaving the Pinch:

CP entering pinch d CP leaving pinch (4.10)

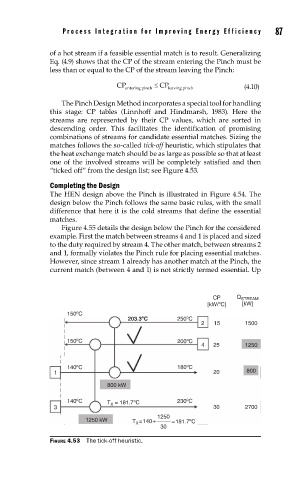

The Pinch Design Method incorporates a special tool for handling

this stage: CP tables (Linnhoff and Hindmarsh, 1983). Here the

streams are represented by their CP values, which are sorted in

descending order. This facilitates the identification of promising

combinations of streams for candidate essential matches. Sizing the

matches follows the so-called tick-off heuristic, which stipulates that

the heat exchange match should be as large as possible so that at least

one of the involved streams will be completely satisfied and then

“ticked off” from the design list; see Figure 4.53.

Completing the Design

The HEN design above the Pinch is illustrated in Figure 4.54. The

design below the Pinch follows the same basic rules, with the small

difference that here it is the cold streams that define the essential

matches.

Figure 4.55 details the design below the Pinch for the considered

example. First the match between streams 4 and 1 is placed and sized

to the duty required by stream 4. The other match, between streams 2

and 1, formally violates the Pinch rule for placing essential matches.

However, since stream 1 already has another match at the Pinch, the

current match (between 4 and 1) is not strictly termed essential. Up

CP Q STREAM

[kW/ºC] [kW]

150ºC

203.3ºC 250ºC

2 15 1500

150ºC 200ºC

4 25 1250

140ºC 180ºC

1 20 800

800 kW

140ºC T X = 181.7ºC 230ºC

3 30 2700

1250

1250 kW T X =140+ =181.7ºC

30

FIGURE 4.53 The tick-off heuristic.