Page 111 - Sustainability in the Process Industry Integration and Optimization

P. 111

88 Cha p te r F o u r

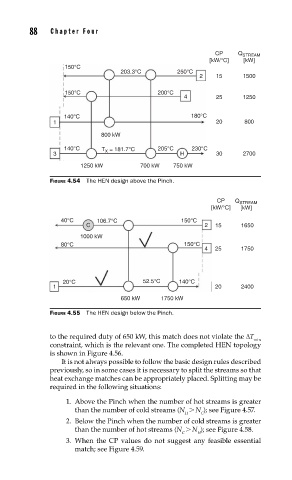

CP Q STREAM

[kW/°C] [kW]

150°C

203.3°C 250°C

2 15 1500

150°C 200°C

4 25 1250

140°C 180°C

1 20 800

800 kW

140°C T X = 181.7°C 205°C 230°C

3 H 30 2700

1250 kW 700 kW 750 kW

FIGURE 4.54 The HEN design above the Pinch.

CP Q STREAM

[kW/°C] [kW]

40°C 106.7°C 150°C

C 2 15 1650

1000 kW

80°C 150°C

4 25 1750

20°C 52.5°C 140°C

1 20 2400

650 kW 1750 kW

FIGURE 4.55 The HEN design below the Pinch.

to the required duty of 650 kW, this match does not violate the ΔT

min

constraint, which is the relevant one. The completed HEN topology

is shown in Figure 4.56.

It is not always possible to follow the basic design rules described

previously, so in some cases it is necessary to split the streams so that

heat exchange matches can be appropriately placed. Splitting may be

required in the following situations:

1. Above the Pinch when the number of hot streams is greater

than the number of cold streams (N > N ); see Figure 4.57.

H C

2. Below the Pinch when the number of cold streams is greater

than the number of hot streams (N > N ); see Figure 4.58.

C H

3. When the CP values do not suggest any feasible essential

match; see Figure 4.59.