Page 138 - Sustainability in the Process Industry Integration and Optimization

P. 138

Ma s s I n t e g r a t i o n 115

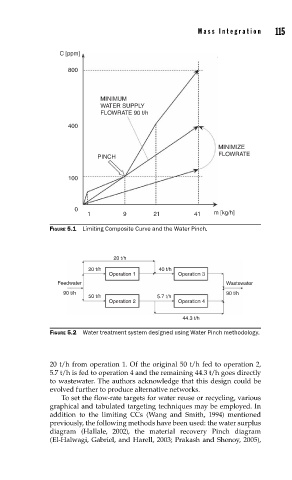

C [ppm]

800

MINIMUM

WATER SUPPLY

FLOWRATE 90 t/h

400

MINIMIZE

FLOWRATE

PINCH

100

0

1 9 21 41 m [kg/h]

FIGURE 5.1 Limiting Composite Curve and the Water Pinch.

20 t/h

20 t/h 40 t/h

Operation 1 Operation 3

Feedwater Wastewater

90 t/h 90 t/h

50 t/h 5.7 t/h

Operation 2 Operation 4

44.3 t/h

FIGURE 5.2 Water treatment system designed using Water Pinch methodology.

20 t/h from operation 1. Of the original 50 t/h fed to operation 2,

5.7 t/h is fed to operation 4 and the remaining 44.3 t/h goes directly

to wastewater. The authors acknowledge that this design could be

evolved further to produce alternative networks.

To set the flow-rate targets for water reuse or recycling, various

graphical and tabulated targeting techniques may be employed. In

addition to the limiting CCs (Wang and Smith, 1994) mentioned

previously, the following methods have been used: the water surplus

diagram (Hallale, 2002), the material recovery Pinch diagram

( El-Halwagi, Gabriel, and Harell, 2003; Prakash and Shenoy, 2005),