Page 243 - Sustainability in the Process Industry Integration and Optimization

P. 243

220 Cha p te r T e n

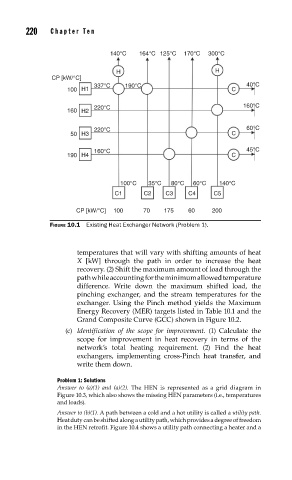

140°C 164°C 125°C 170°C 300°C

H H

CP [kW/°C]

337°C 190°C 40°C

100 H1 C

220°C 160°C

160 H2

220°C 60°C

50 H3 C

160°C 45°C

190 H4 C

100°C 35°C 80°C 60°C 140°C

C1 C2 C3 C4 C5

CP [kW/°C] 100 70 175 60 200

FIGURE 10.1 Existing Heat Exchanger Network (Problem 1).

temperatures that will vary with shifting amounts of heat

X [kW] through the path in order to increase the heat

recovery. (2) Shift the maximum amount of load through the

path while accounting for the minimum allowed temperature

difference. Write down the maximum shifted load, the

pinching exchanger, and the stream temperatures for the

exchanger. Using the Pinch method yields the Maximum

Energy Recovery (MER) targets listed in Table 10.1 and the

Grand Composite Curve (GCC) shown in Figure 10.2.

(c) Identification of the scope for improvement. (1) Calculate the

scope for improvement in heat recovery in terms of the

network’s total heating requirement. (2) Find the heat

exchangers, implementing cross-Pinch heat transfer, and

write them down.

Problem 1: Solutions

Answer to (a)(1) and (a)(2). The HEN is represented as a grid diagram in

Figure 10.3, which also shows the missing HEN parameters (i.e., temperatures

and loads).

Answer to (b)(1). A path between a cold and a hot utility is called a utility path.

Heat duty can be shifted along a utility path, which provides a degree of freedom

in the HEN retrofit. Figure 10.4 shows a utility path connecting a heater and a