Page 123 - Materials Chemistry, Second Edition

P. 123

Ch003-P373623.qxd 3/22/07 5:29 PM Page 102

Sustainable Industrial Design and Waste Management

102

1. Surface

2. Gas 1972 Statoil water 1961

refinery Lake Tisso

Gyproc 9. Steam 1982 3. 1973

5. Fly Ash 1979 Asnaes 8. Steam 1982

power station

6. Heat 1980/89

NovoNordisk

Cement Fish

7. Heat 1982 +

industry farms

Novozymes

4. Biomass/

NovoGro 1976

The Municipality Farms

of Kalundborg

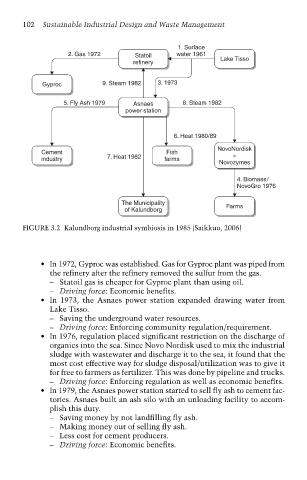

FIGURE 3.2 Kalundborg industrial symbiosis in 1985 (Saikkuu, 2006)

• In 1972, Gyproc was established. Gas for Gyproc plant was piped from

the refinery after the refinery removed the sulfur from the gas.

– Statoil gas is cheaper for Gyproc plant than using oil.

– Driving force: Economic benefits.

• In 1973, the Asnaes power station expanded drawing water from

Lake Tisso.

– Saving the underground water resources.

– Driving force: Enforcing community regulation/requirement.

• In 1976, regulation placed significant restriction on the discharge of

organics into the sea. Since Novo Nordisk used to mix the industrial

sludge with wastewater and discharge it to the sea, it found that the

most cost effective way for sludge disposal/utilization was to give it

for free to farmers as fertilizer. This was done by pipeline and trucks.

– Driving force: Enforcing regulation as well as economic benefits.

• In 1979, the Asnaes power station started to sell fly ash to cement fac-

tories. Asnaes built an ash silo with an unloading facility to accom-

plish this duty.

– Saving money by not landfilling fly ash.

– Making money out of selling fly ash.

– Less cost for cement producers.

– Driving force: Economic benefits.