Page 79 - Materials Chemistry, Second Edition

P. 79

Ch002-P373623.qxd 3/22/07 5:27 PM Page 60

Sustainable Industrial Design and Waste Management

60

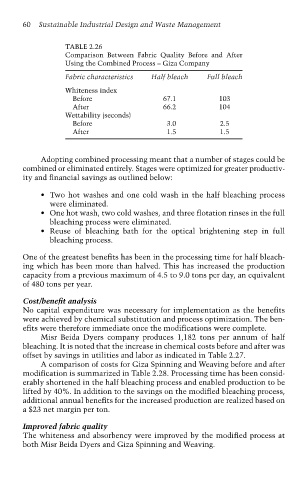

TABLE 2.26

Comparison Between Fabric Quality Before and After

Using the Combined Process – Giza Company

Fabric characteristics Half bleach Full bleach

Whiteness index

Before 67.1 103

After 66.2 104

Wettability (seconds)

Before 3.0 2.5

After 1.5 1.5

Adopting combined processing meant that a number of stages could be

combined or eliminated entirely. Stages were optimized for greater productiv-

ity and financial savings as outlined below:

• Two hot washes and one cold wash in the half bleaching process

were eliminated.

• One hot wash, two cold washes, and three flotation rinses in the full

bleaching process were eliminated.

• Reuse of bleaching bath for the optical brightening step in full

bleaching process.

One of the greatest benefits has been in the processing time for half bleach-

ing which has been more than halved. This has increased the production

capacity from a previous maximum of 4.5 to 9.0 tons per day, an equivalent

of 480 tons per year.

Cost/benefit analysis

No capital expenditure was necessary for implementation as the benefits

were achieved by chemical substitution and process optimization. The ben-

efits were therefore immediate once the modifications were complete.

Misr Beida Dyers company produces 1,182 tons per annum of half

bleaching. It is noted that the increase in chemical costs before and after was

offset by savings in utilities and labor as indicated in Table 2.27.

A comparison of costs for Giza Spinning and Weaving before and after

modification is summarized in Table 2.28. Processing time has been consid-

erably shortened in the half bleaching process and enabled production to be

lifted by 40%. In addition to the savings on the modified bleaching process,

additional annual benefits for the increased production are realized based on

a $23 net margin per ton.

Improved fabric quality

The whiteness and absorbency were improved by the modified process at

both Misr Beida Dyers and Giza Spinning and Weaving.