Page 83 - Materials Chemistry, Second Edition

P. 83

Ch002-P373623.qxd 3/22/07 5:27 PM Page 64

Sustainable Industrial Design and Waste Management

64

• Final fabric products are not given adequate protection during storage,

so that soilage can easily occur.

• Various parts of steam and hot water pipes are not insulated and a

great amount of heat is lost.

• Steam condensate from all departments is put directly to the drain

rather than re-circulated as feed water, causing an unnecessary wastage

of water.

• Huge amounts of thermal energy are lost in the flue gases of the boiler

which are exhausted to air.

• Considerable amounts of hot effluent from the different units in the

pre-treatment and dyeing departments are directly discharged to the

sewer, with great heat losses.

• Huge quantities of final washing water in the bleaching ranges are

directly discharged without reuse.

The measures which have been identified for implementation are briefly

outlined below. During the audit stage, particular attention was paid to

those improvements that could be carried out at low or no cost to the fac-

tory. These are easy to implement and often entail significant savings.

CP techniques implemented

• Improve storage facilities – dyes and fabrics (good housekeeping): The

storage conditions in the dyehouse store were investigated and rec-

ommendations made to prevent the hydrolysis and lumping of reac-

tive dyestuffs, which was achieved by ensuring that the dye containers

were tightly closed and the storage space was closed when not in use.

• Material substitution and optimization of chemical usage (input mate-

rial change): The different process chemicals used in the factory were

thoroughly examined, with the aim of identifying optimum process

chemicals, taking into account process and fabric requirements,

resource, and environmental constraints. The following alternatives

were identified:

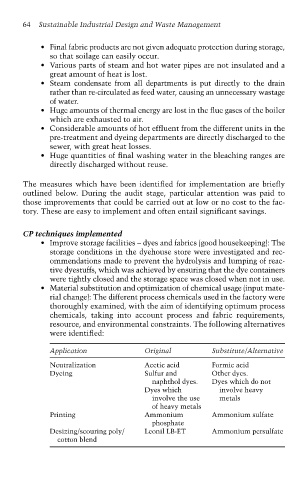

Application Original Substitute/Alternative

Neutralization Acetic acid Formic acid

Dyeing Sulfur and Other dyes.

naphthol dyes. Dyes which do not

Dyes which involve heavy

involve the use metals

of heavy metals

Printing Ammonium Ammonium sulfate

phosphate

Desizing/scouring poly/ Leonil LB-ET Ammonium persulfate

cotton blend