Page 86 - Materials Chemistry, Second Edition

P. 86

Ch002-P373623.qxd 3/22/07 5:27 PM Page 67

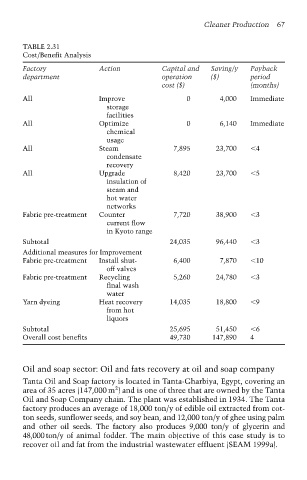

TABLE 2.31 Cleaner Production 67

Cost/Benefit Analysis

Factory Action Capital and Saving/y Payback

department operation ($) period

cost ($) (months)

All Improve 0 4,000 Immediate

storage

facilities

All Optimize 0 6,140 Immediate

chemical

usage

All Steam 7,895 23,700 4

condensate

recovery

All Upgrade 8,420 23,700 5

insulation of

steam and

hot water

networks

Fabric pre-treatment Counter 7,720 38,900 3

current flow

in Kyoto range

Subtotal 24,035 96,440 3

Additional measures for Improvement

Fabric pre-treatment Install shut- 6,400 7,870 10

off valves

Fabric pre-treatment Recycling 5,260 24,780 3

final wash

water

Yarn dyeing Heat recovery 14,035 18,800 9

from hot

liquors

Subtotal 25,695 51,450 6

Overall cost benefits 49,730 147,890 4

Oil and soap sector: Oil and fats recovery at oil and soap company

Tanta Oil and Soap factory is located in Tanta-Gharbiya, Egypt, covering an

2

area of 35 acres (147,000 m ) and is one of three that are owned by the Tanta

Oil and Soap Company chain. The plant was established in 1934. The Tanta

factory produces an average of 18,000 ton/y of edible oil extracted from cot-

ton seeds, sunflower seeds, and soy bean, and 12,000 ton/y of ghee using palm

and other oil seeds. The factory also produces 9,000 ton/y of glycerin and

48,000ton/y of animal fodder. The main objective of this case study is to

recover oil and fat from the industrial wastewater effluent (SEAM 1999a).