Page 81 - Materials Chemistry, Second Edition

P. 81

Ch002-P373623.qxd 3/22/07 5:27 PM Page 62

Sustainable Industrial Design and Waste Management

62

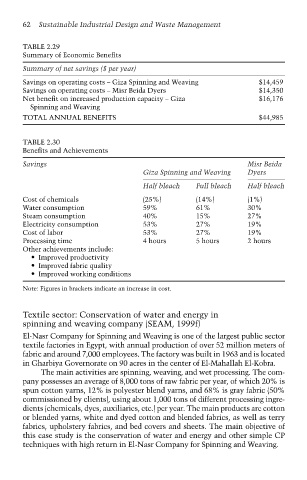

TABLE 2.29

Summary of Economic Benefits

Summary of net savings ($ per year)

Savings on operating costs – Giza Spinning and Weaving $14,459

Savings on operating costs – Misr Beida Dyers $14,350

Net benefit on increased production capacity – Giza $16,176

Spinning and Weaving

TOTAL ANNUAL BENEFITS $44,985

TABLE 2.30

Benefits and Achievements

Savings Misr Beida

Giza Spinning and Weaving Dyers

Half bleach Full bleach Half bleach

Cost of chemicals (25%) (14%) (1%)

Water consumption 59% 61% 30%

Steam consumption 40% 15% 27%

Electricity consumption 53% 27% 19%

Cost of labor 53% 27% 19%

Processing time 4 hours 5 hours 2 hours

Other achievements include:

• Improved productivity

• Improved fabric quality

• Improved working conditions

Note: Figures in brackets indicate an increase in cost.

Textile sector: Conservation of water and energy in

spinning and weaving company (SEAM, 1999f)

El-Nasr Company for Spinning and Weaving is one of the largest public sector

textile factories in Egypt, with annual production of over 52 million meters of

fabric and around 7,000 employees. The factory was built in 1963 and is located

in Gharbiya Governorate on 90 acres in the center of El-Mahallah El-Kobra.

The main activities are spinning, weaving, and wet processing. The com-

pany possesses an average of 8,000 tons of raw fabric per year, of which 20% is

spun cotton yarns, 12% is polyester blend yarns, and 68% is gray fabric (50%

commissioned by clients), using about 1,000 tons of different processing ingre-

dients (chemicals, dyes, auxiliaries, etc.) per year. The main products are cotton

or blended yarns, white and dyed cotton and blended fabrics, as well as terry

fabrics, upholstery fabrics, and bed covers and sheets. The main objective of

this case study is the conservation of water and energy and other simple CP

techniques with high return in El-Nasr Company for Spinning and Weaving.