Page 84 - Materials Chemistry, Second Edition

P. 84

Ch002-P373623.qxd 3/22/07 5:27 PM Page 65

Cleaner Production

Feeding water 65

1 2 3 4 5 6 7 8

Draining water

Kyoto bleaching unit before modification

Feeding water

1 2 3 4 5 6 7 8

Draining water

Kyoto bleaching unit after modification

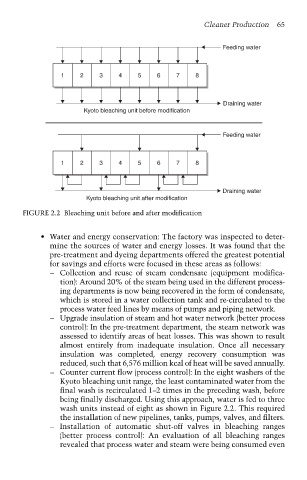

FIGURE 2.2 Bleaching unit before and after modification

• Water and energy conservation: The factory was inspected to deter-

mine the sources of water and energy losses. It was found that the

pre-treatment and dyeing departments offered the greatest potential

for savings and efforts were focused in these areas as follows:

– Collection and reuse of steam condensate (equipment modifica-

tion): Around 20% of the steam being used in the different process-

ing departments is now being recovered in the form of condensate,

which is stored in a water collection tank and re-circulated to the

process water feed lines by means of pumps and piping network.

– Upgrade insulation of steam and hot water network (better process

control): In the pre-treatment department, the steam network was

assessed to identify areas of heat losses. This was shown to result

almost entirely from inadequate insulation. Once all necessary

insulation was completed, energy recovery consumption was

reduced, such that 6,576 million kcal of heat will be saved annually.

– Counter current flow (process control): In the eight washers of the

Kyoto bleaching unit range, the least contaminated water from the

final wash is recirculated 1–2 times in the preceding wash, before

being finally discharged. Using this approach, water is fed to three

wash units instead of eight as shown in Figure 2.2. This required

the installation of new pipelines, tanks, pumps, valves, and filters.

– Installation of automatic shut-off valves in bleaching ranges

(better process control): An evaluation of all bleaching ranges

revealed that process water and steam were being consumed even