Page 80 - Materials Chemistry, Second Edition

P. 80

Ch002-P373623.qxd 3/22/07 5:27 PM Page 61

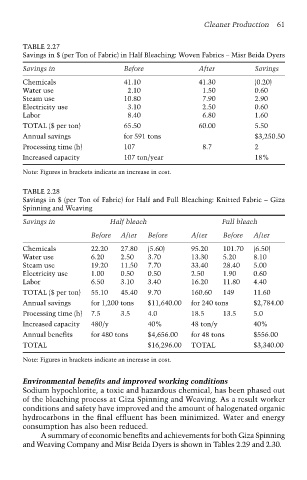

TABLE 2.27 Cleaner Production 61

Savings in $ (per Ton of Fabric) in Half Bleaching: Woven Fabrics – Misr Beida Dyers

Savings in Before After Savings

Chemicals 41.10 41.30 (0.20)

Water use 2.10 1.50 0.60

Steam use 10.80 7.90 2.90

Electricity use 3.10 2.50 0.60

Labor 8.40 6.80 1.60

TOTAL ($ per ton) 65.50 60.00 5.50

Annual savings for 591 tons $3,250.50

Processing time (h) 107 8.7 2

Increased capacity 107 ton/year 18%

Note: Figures in brackets indicate an increase in cost.

TABLE 2.28

Savings in $ (per Ton of Fabric) for Half and Full Bleaching: Knitted Fabric – Giza

Spinning and Weaving

Savings in Half bleach Full bleach

Before After Before After Before After

Chemicals 22.20 27.80 (5.60) 95.20 101.70 (6.50)

Water use 6.20 2.50 3.70 13.30 5.20 8.10

Steam use 19.20 11.50 7.70 33.40 28.40 5.00

Electricity use 1.00 0.50 0.50 2.50 1.90 0.60

Labor 6.50 3.10 3.40 16.20 11.80 4.40

TOTAL ($ per ton) 55.10 45.40 9.70 160.60 149 11.60

Annual savings for 1,200 tons $11,640.00 for 240 tons $2,784.00

Processing time (h) 7.5 3.5 4.0 18.5 13.5 5.0

Increased capacity 480/y 40% 48 ton/y 40%

Annual benefits for 480 tons $4,656.00 for 48 tons $556.00

TOTAL $16,296.00 TOTAL $3,340.00

Note: Figures in brackets indicate an increase in cost.

Environmental benefits and improved working conditions

Sodium hypochlorite, a toxic and hazardous chemical, has been phased out

of the bleaching process at Giza Spinning and Weaving. As a result worker

conditions and safety have improved and the amount of halogenated organic

hydrocarbons in the final effluent has been minimized. Water and energy

consumption has also been reduced.

A summary of economic benefits and achievements for both Giza Spinning

and Weaving Company and Misr Beida Dyers is shown in Tables 2.29 and 2.30.