Page 65 - Synthetic Fuels Handbook

P. 65

NATURAL GAS 53

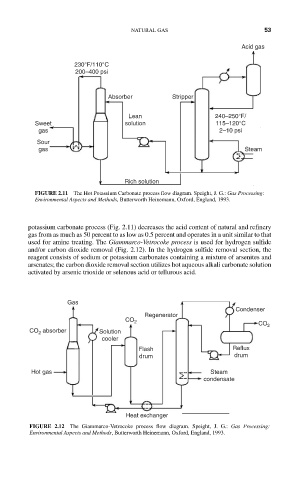

Acid gas

230°F/110°C

200–400 psi

Absorber Stripper

Lean 240–250°F/

Sweet solution 115–120°C

gas 2–10 psi

Sour

gas Steam

Rich solution

FIGURE 2.11 The Hot Potassium Carbonate process flow diagram. Speight, J. G.: Gas Processing:

Environmental Aspects and Methods, Butterworth Heinemann, Oxford, England, 1993.

potassium carbonate process (Fig. 2.11) decreases the acid content of natural and refinery

gas from as much as 50 percent to as low as 0.5 percent and operates in a unit similar to that

used for amine treating. The Giammarco-Vetrocoke process is used for hydrogen sulfide

and/or carbon dioxide removal (Fig. 2.12). In the hydrogen sulfide removal section, the

reagent consists of sodium or potassium carbonates containing a mixture of arsenites and

arsenates; the carbon dioxide removal section utilizes hot aqueous alkali carbonate solution

activated by arsenic trioxide or selenous acid or tellurous acid.

Gas

Condenser

Regenerator

CO 2 CO

CO absorber Solution 2

2

cooler

Flash Reflux

drum drum

Hot gas Steam

condensate

Heat exchanger

FIGURE 2.12 The Giammarco-Vetrocoke process flow diagram. Speight, J. G.: Gas Processing:

Environmental Aspects and Methods, Butterworth Heinemann, Oxford, England, 1993.