Page 64 - Synthetic Fuels Handbook

P. 64

52 CHAPTER TWO

to enhance the methanol recovery. The IFPEXOL-2 process for acid gas removal is very

similar to an amine-type process except for the operating temperatures. The absorber

operates below −20°F to minimize methanol losses, and the regenerator operates at about

90 psi. Cooling is required on the regenerator condenser to recover the methanol. This pro-

cess usually follows the IFPEXOL-1 process so excessive hydrocarbon absorption is not

as great a problem (Minkkinen and Jonchere, 1997).

2.7.5 Carbonate-Washing and Water-Washing Processes

Carbonate washing is a mild alkali process for emission control by the removal of acid

gases (such as carbon dioxide and hydrogen sulfide) from gas streams (Speight, 1993,

2007b) and uses the principle that the rate of absorption of carbon dioxide by potassium

carbonate increases with temperature. It has been demonstrated that the process works best

near the temperature of reversibility of the reactions:

K CO + CO + H O → 2KHCO

2 3 2 2 3

K CO + H S → KHS + KHCO 3

2

3

2

Water washing, in terms of the outcome, is analogous to washing with potassium

carbonate (Kohl and Riesenfeld, 1985), and it is also possible to carry out the desorption

step by pressure reduction. The absorption is purely physical and there is also a relatively

high absorption of hydrocarbons, which are liberated at the same time as the acid gases.

The process using potassium phosphate is known as phosphate desulphurization, and it

is used in the same way as the Girbotol process to remove acid gases from liquid hydrocar-

bons as well as from gas streams. The treatment solution is a water solution of tripotassium

phosphate (K PO ), which is circulated through an absorber tower and a reactivator tower

3

4

in much the same way as the ethanolamine is circulated in the Girbotol process; the solution

is regenerated thermally.

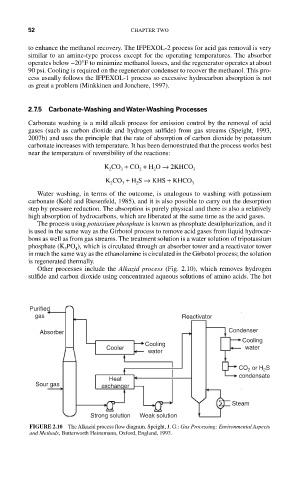

Other processes include the Alkazid process (Fig. 2.10), which removes hydrogen

sulfide and carbon dioxide using concentrated aqueous solutions of amino acids. The hot

Purified

gas Reactivator

Absorber Condenser

Cooling

Cooling

Cooler water

water

CO or H S

2

2

condensate

Heat

Sour gas exchanger

Steam

Strong solution Weak solution

FIGURE 2.10 The Alkazid process flow diagram. Speight, J. G.: Gas Processing: Environmental Aspects

and Methods, Butterworth Heinemann, Oxford, England, 1993.