Page 59 - Synthetic Fuels Handbook

P. 59

NATURAL GAS 47

Acid gas

Cooler

Purified

gas Lean

solution

Rich

solution

Absorber Cooler Regenator

(high pressure, (low pressure,

low temperature) boiling)

Gas and

acid gas Heat

exchanger

Steam

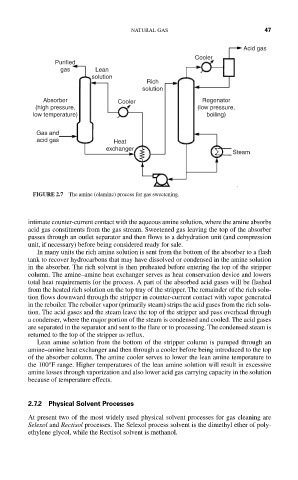

FIGURE 2.7 The amine (olamine) process for gas sweetening.

intimate counter-current contact with the aqueous amine solution, where the amine absorbs

acid gas constituents from the gas stream. Sweetened gas leaving the top of the absorber

passes through an outlet separator and then flows to a dehydration unit (and compression

unit, if necessary) before being considered ready for sale.

In many units the rich amine solution is sent from the bottom of the absorber to a flash

tank to recover hydrocarbons that may have dissolved or condensed in the amine solution

in the absorber. The rich solvent is then preheated before entering the top of the stripper

column. The amine–amine heat exchanger serves as heat conservation device and lowers

total heat requirements for the process. A part of the absorbed acid gases will be flashed

from the heated rich solution on the top tray of the stripper. The remainder of the rich solu-

tion flows downward through the stripper in counter-current contact with vapor generated

in the reboiler. The reboiler vapor (primarily steam) strips the acid gases from the rich solu-

tion. The acid gases and the steam leave the top of the stripper and pass overhead through

a condenser, where the major portion of the steam is condensed and cooled. The acid gases

are separated in the separator and sent to the flare or to processing. The condensed steam is

returned to the top of the stripper as reflux.

Lean amine solution from the bottom of the stripper column is pumped through an

amine–amine heat exchanger and then through a cooler before being introduced to the top

of the absorber column. The amine cooler serves to lower the lean amine temperature to

the 100°F range. Higher temperatures of the lean amine solution will result in excessive

amine losses through vaporization and also lower acid gas carrying capacity in the solution

because of temperature effects.

2.7.2 Physical Solvent Processes

At present two of the most widely used physical solvent processes for gas cleaning are

Selexol and Rectisol processes. The Selexol process solvent is the dimethyl ether of poly-

ethylene glycol, while the Rectisol solvent is methanol.